Have you ever wondered how those vibrantly painted boards that you see in shops are made? This is done with the help of a unique machine, this unique device uses polyvinyl chloride in its product formation which gets combined with other things as per required and hence form pvc foam board making it harder. Each of these instruments that are offered transfer raw materials to colourful boards which may be best for an art venture, a sign or even exhibition. Now, let us look at the basic mechanism of this machine and understand why it is specifically required for manufacturing high standard foam boards.

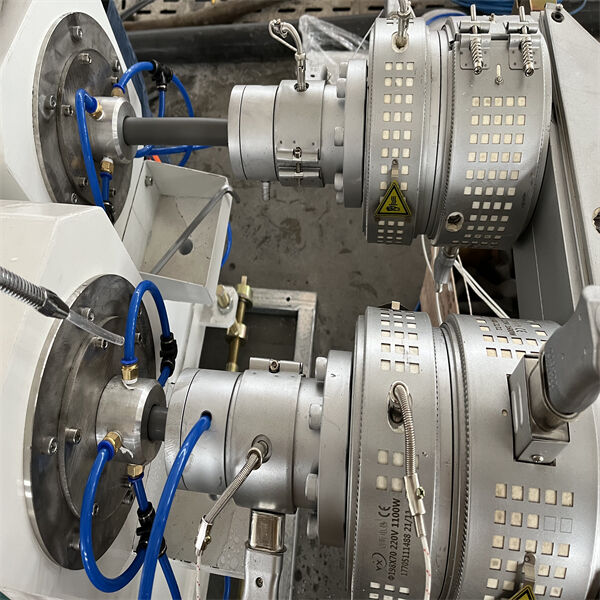

An essential part of being able to produce PVC foam boards is having the right machine. The machine needs to be well maintained for the boards to turn out good. These days, the most modern PVC foam board machines are quite sophisticated. They can, for instance, control temperature very accurately in order to get the materials hot enough to melt and merge properly. These machines can also produce boards fast which is very beneficial when producing many of them. They can also automatically cut and shape the boards, meaning time is saved as each board is made to the correct specifications! These features combine to deliver the finest foam boards around.

If a PVC foam board is of good quality, then the process in which it was made with the use of a PVC foam board machine would be much faster and less expensive. The reason for this is that a single machine can make hundreds of boards at once, so you willbe able to get many products manufactured with in very less time. They are waste light, which is friendly to the environment (and good for fees). In addition, these machines place lower demands on energy consumption than obsolete machines. You are able to make boards simply and swiftly, letting you concentrate on fulfilling other responsibilities.

Research has been conducted to improve upon the technology of PVC foam boards. PVC foam board machines today produce boards ranging in various thicknesses an densities. This means that you can make the board as thick or strong as you want in order to suit its purpose. The machines have upgraded cooling systems which maintain the boards flat and smooth. In addition to securing the boards against bending or warping, these cooling mechanisms help ensure that the finish product looks amazing and is ready to use almost immediately.

Perhaps one of the best parts about PVC foam board machines is that they can even be custom tailored to suit your requirements. If you can imagine a board in any thickness or color, or shape for that matter then there is probably an industrial woodworking machine out there to make it. In this way, you will be able to make boards for the various projects that would require modularity. They come in a range of sizes - from small machines that you might have at home, all the way through to huge monsters for giant factories. So we get the right machine for you, whether you're making 10 boards or a million.

The manufacturing of PVC foam board is an automated process, and using PVC foam boards cutting machine will have a production line up to 384 per hour. They are designed to help you create more boards faster and easier. A lot of these machines are created to assist save time and also energy throughout the production_COMPANY NAME process. Examples such as a unique background to detect and transport the boards automatically by some machines. This means that workers do not have to perform a large amount is manual labor which speeds up the whole process and makes it more efficient. So stop wasting time and effort when creating boards using these smart design approaches.

Pre-Sales: Our sales staff, with over Pvc foam board machine of experience, will recommend the best machine configuration for you. We provide 7*24h service to our clients and provide videos of the factory.In-Sales: Our videos demonstrate the manufacturing process starting from raw steel through to finished products.After-Sales Services: Our engineers offer services on-site at cost and lifelong technical support via video starting from raw materials until the completed product.

At Jiangsu Xinhe we adhere to stringent standards regarding the thickness and materials of machine steel and provide the most areas that are at risk Pvc foam board machine safety measures our production lines offer long life span with low failure rates and a stable efficient production Many of our customers have been using their machines for more then 8 years

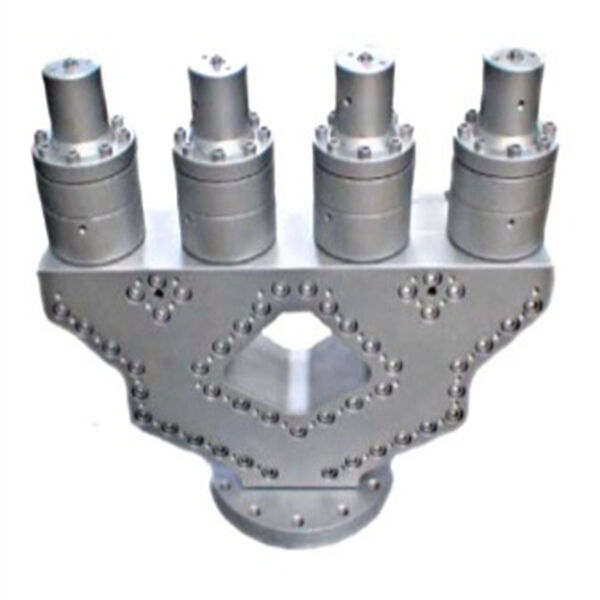

With over 12 years of experience in Pvc foam board machine, we offer machines that can be customized in terms of color, size, and even automation levels. We can also customize molds based on the finished product. We've evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently one of China's top 10 extrusion lines made of plastic.

Our machines are configured to meet the demands of the client We offer factory-direct sales high-quality items as well as an extensive after-sales support Our machines have a lifespan that Pvc foam board machine 8 years They have been well-received by our customers from Vietnam Indonesia Saudi Arabia South Africa Bolivia as well as other regions

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy