Ever wondered how those foam boards used in signs, advertising displays or even furniture are made? These are also manufactured by special machine called PVC foam board making machine. The construction foam board produced by this machine is light but strong, which makes its surface smooth. These traits make them really very effective in numerous other particular niches.

Foamed PVC Board production

The plastic foam process begins by mixing the PVC resin with a variety of other ingredients. All together are formed into large molds and have an active density. After, it is spread out onto a flat surface. Then the pomace is heated. As it heats up, the batter will expand and foamy, like bread baking. Pressing and Cutting Shapes Once out of the steam, foam is pressed into even blocks before being trimmed to fit various sizes.

This may come up another time named a shut cell froth structure. This unique design also helps make the foam board waterproof (meaning it is highly resistant or impervious to water), and prevents moisture penetrations from damaging them. It additionally offers to maintain the temperature stable (either hot or maybe cold). There are also special additives that can be formulated or poured in to solidify the foam board even more and keep it safe against fire. The boards have a longer life, they can last more than other types of board making them safer to use.

Small businesses can be expensive to start, so purchasing a low cost PVC foam board machine allows the business owner to create their own foam boards instead of buying from others. This permits them to cut costs and earn significantly more revenue. You can easily use and start to use this Xinhe pvc foam board machine, they are design with free user interfaces. This makes them an intelligent investment for small companies with plans to expand.

One can easily learn about operating the machine, even if a new user. Everyone gets used to the machine really quickly as there are a lot of guides and training video available. Automatic shut-off and an emergency stop should also be standard features to ensure operator safety while the machine is in operation. They can be confident and rely on the Xinhe pvc foam board manufacturing machine.

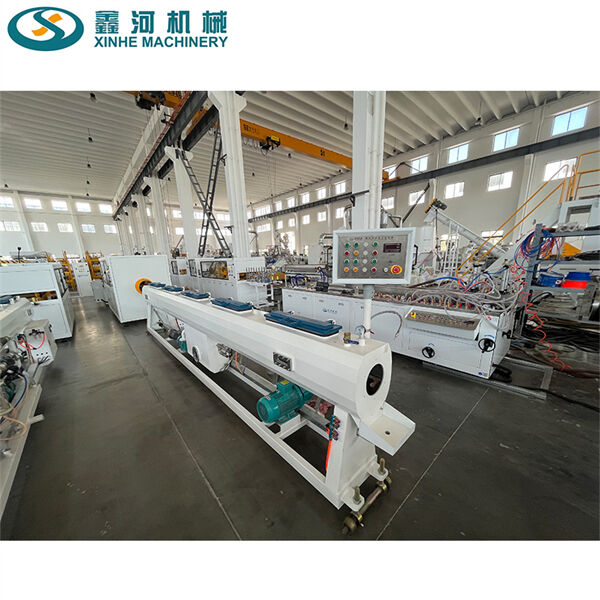

In the case of large producers, high production volumes at short time are crucial for foam boards So many PVC foam board making machines are auto-line. This is why Xinhe pvc foam board making machine can produce foam boards much faster without the need to be accompanied with lots of hands. A greater system utilization may prove to be great boon for companies which ultimately means they save on labor costs.

Because cutting and shaping parts of the machine are functioning automatically, foam boards will be cut properly every time. It also includes an auto quality check that finds errors on foam boards too. If any defects are detected, those boards would be pulled off the manufacturing line. This makes insure quality of the end product which is one of its kinds as per manufacturers.

Pre-Sales: With more than five years of industry experience, our sales team will recommend to you the right Pvc foam board making machine. We offer a 24-hour service to our customers and provide video tours of our factory.In-Sales: Our videos show the production process, from raw steel right through to the final products.After-Sales Service: Our engineers provide an on-site service at a cost and lifetime video technical support from raw materials to finished products.

We Pvc foam board making machine the machine configuration to the specific needs of our customers We also provide factory direct sales premium product quality as well as a complete after-sales support Our machines are adored by our customers in Vietnam as well as Indonesia Additionally they enjoy a long lifespan lasting for more than 8 years

We offer customized machines in terms of size, color and automation. Molds are customizable in accordance with what the final product is expected to look like. We've evolved from Pvc foam board making machine and have become one of the top 10 Chinese extrusion lines made of plastic.

We adhere to the strictest standards for Jiangsu Xinhe for machine steel thickness and materials We also offer an inventory of components that are vulnerable The Pvc foam board making machine we use are built to guarantee safety and have a long life expectancy as well as a low rate of failure and stable efficient production Many of our customers have utilized their machines for more than eight years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy