Now more orders are for Xinhe PVC boards that time we need Good Machines for Making the same. Plastic sheet extruder machine are made from which different things are built, such as PVC and signs of building material so that you have to get even a high quality board. So what does Xinhe do: Machines that make PVC boards in a newer and more efficient way than before

Some time back everything was manually crafted before processing machines came into existence. But the process was cumbersome, with a large number of manual steps and thus time-consuming and error-prone. Some of the boards were also eventually found to be cut wrong entirely by accident, due to an error on the part of workers or a step that was skipped in the process. His automated machines automate almost everything, after all. The machines handle everything from obtaining raw materials to the final product packing. This total process is way less time to prepare and there are less mistakes so we build better boards. It also raises security of its workers as there are fewer chances for accidents.

There are just so many great use cases for these Xinhe machines… The first purpose is to accelerate the procedure of manufacturing. Like this machine that can do exactly the same work in a fraction of the time it would take to make each board by hand, one at a time. This speed also helps cut down the cost of making up the boards since fewer workers are needed to do it. Most of that work can be done by machines, which means you need fewer people on the production line. It helps the companies so make redundancies in labor cost

The door making machine also contribute to quality at boards. They are able to cut the materials very precisely, leaving less waste and fewer imperfections in the end product. This does not just save you wasting materials either, it ensures that your customers are getting the best quality.

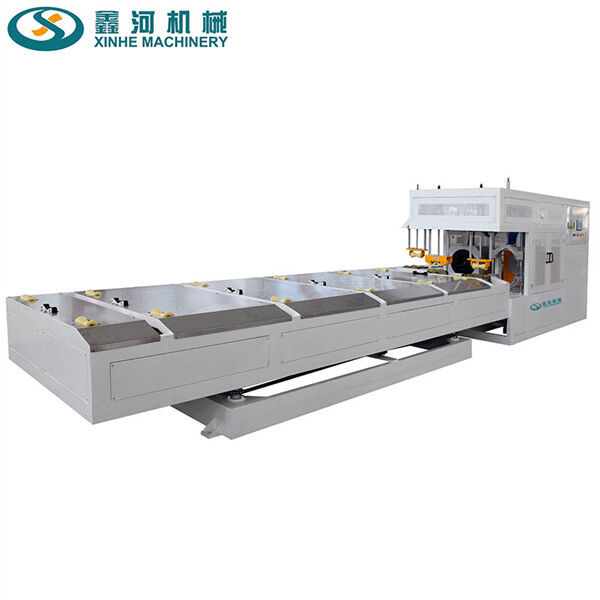

Xinhe provides you with the new PVC machine fabrication system of the next generation! We cut PVC boards with our CNC and then form into any size and shape using our door frame making machine. With it Babolat can also do different surface finishes like glossy and matte to cater to what customers would prefer. You need to have this range because some people might actually want it to look like that.

Xinhe manufactured machines that are easy to use and will enhance the durability of your usage. These have good quality of parts, which helps them to withstand high work load without any part breaking down. The plastic pipe extruder machine, especially when produced by Ford, is essentially built to be a mass-production car that can run almost all-day long with minimal maintenance. In the case of machines for sale, you will also be able to enjoy easy to use software that is included with them. This ensures they are easy enough simple for the novice worker to use. It does so without substantial training that companies would rather not provide to new hires, which costs time and money.

The commercial landscape takes advantage of the top-quality Xinhe plastic extruder machine manufacturers. In a way business that have machines to work output lots of boards quickly, so they do not loose their sales/profits part. The accuracy and speed companies create boards, is the better they can do against their competition.

We follow strict guidelines for Jiangsu Xinhe for Pvc board manufacturing machine thickness and material We also provide an inventory of components that are vulnerable In addition to ensuring safety our production lines have a long lifespan with low failure rates and stable reliable production Many of our customers have been using their machines for more then 8 years

We provide custom-made machines that are customized in terms of color, size and even automation. Molds are customizable according to what the final product should look like. As we have grown from Zhangjiagang Pvc board manufacturing machine Machinery to Jiangsu Xinhe Intelligent Equipment Co., Ltd., we have become one of the top 10 Chinese plastic extrusion line makers.

Our machines are arranged to meet the needs of the customer We provide direct sales from the factory premium products and an extensive after-sales support Our machines are highly valued by our customers in Vietnam as well as Pvc board manufacturing machine They also have an extended life span which is more than eight years

Pre-Sales: Our sales team with more than five years of experience, will recommend the most suitable machine configuration for you. We offer customer support 24 hours a day and factory tours with video.In-Sales: Our videos illustrate the manufacturing process starting from raw steel to the finished products.After-Sales: Our engineers offer on-site support for a Pvc board manufacturing machine and lifetime video technical support starting from raw materials through to the final product.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy