So... I have this really cool thing, and its called a WPC board machine! The equipment is a unique machine by which high-quality new boards are made from novel materials, environmentally friendly. You can use these boards for, well anything really in regards to decks or fences and even furniture! In Today I will introduce some of the things that WPC board machines, and why it is good for our earth, but also improve the home building industry. I am also going to provide you some games advice and show you how the best way is to use these machines in order to make more money.

WPC: Wood-Plastic Composite. Thus, the boards crafted by a WPC board machine are actually wood is most important and plastic in some level. The boards are strong and robust, thanks to a unique mixture of bamboo. Well, how does the contraption actually function? It first hacks the wood and plastic to meticulous pieces - like you might do with a pair of scissors, only at light-speed. These pieces are later mixed with a variety of added ingredients that will help make the boards stronger and better. Then the mixture is heated and formed by a mold (similar to that of cutting out cookies). After this, your WPC board will be gotten ready to use perfectly for all of your projects and ideas!

WPC Board Machines Saves Environments: The best part about the wpc board machines is that they prove to be creating boards that are eco-friendly! WPC board consists of wood and plastic. The biggest advantage when using WPC boards is exempting waste used to go landfills as the form, causing a severe impact towards our planet Earth; they are renewable each year which means you could contribute zero tax-paying landfill charges if disposed at your earliest convenience after their life cycle has ended.... These boards are long lasting so you will not have to replace them like other materials such as wood or metal, regularly. A great choice for anyone looking to produce something that is both eco-friendly and sustainable due in part to the savings on resources over time. Since being made using recycled material, WPC boards help save trees -- an eco-friendly company!

The WPC board machines have played a great role in building the constructionary. Outdoor Decks, Fences & BenchesAlthough these boards are strong and long lasting they have been wildly popular in outdoor decks, fences, and benches! They are also water and pest resistant, so that they can be used for outdoor use. They are designed to be durable and weather-proof so they can continue looking great and functioning well for years. They are also an eco-friendly option which is good for the environment and many people already have started preferring it over traditional building materials. Builders like using WPC boards as they are environmentally friendly and still work efficiently.

For those who have an interest in the WPC board machine, you could find a number of how to go about obtaining assistance performing and getting more advantageous. The first step is to have everything ready with you as tools and material in order to start the project. Doing so will prevent any lags or wait time that may get in your way. You should also train anyone who will use the machine. By putting in the time to teach them how to properly use your machine that will help things go more smoothly and you get the most out of your new appliance. You obviously can not show up alone to do all this work, that is why the effective crew itself is a no less valuable asset whose value only increases over time since their functions/positions improve and head toward success together-which in turn will allow you as an entrepreneur tear off new heights of discovery also reduce the cycle (we remind) therefore increasing productivity.

ConclusionSo, now we have mentioned everything about how buying a WPC board machine is cost effective in the long run. Sure, these machines might come with a little bit of an upfront price tag but they pay for themselves in the long run. You would save a considerable amount of money in repairs and replacements because WPC boards are long-lasting do not demand as much fixing. Not only this but if you make your own WPC boards through an extrusion plant, you can charge less against costlier construction materials and that in return helps to maximise profits. Being able to make your own materials allows you more control over the cost, which in turn translates into increased profits for better prices and helps to ensure a successful long-term business.

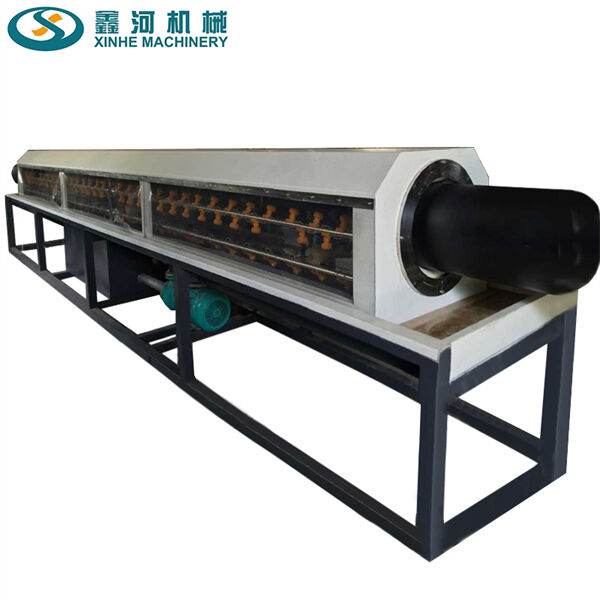

We tailor the machine Wpc board machine to the specific needs of our customers We also provide factory direct sales high product quality and comprehensive after-sales support Our machines are highly regarded by our clients in Vietnam as well as Indonesia Additionally they have longevity that lasts longer than eight years

Pre-Sales: Our Wpc board machine who have more than 5 years of experience, can suggest the right machine configuration to you. We provide 7*24h service to our clients and offer video tours of the factory.In-Sales: Our videos show the production process from raw steel right through to the final products.After-Sales: Our experts provide an on-site service at a cost, and lifelong video technical support from raw materials to finished products.

With 12 years of experience in plastic extrusion, we offer machines that can be customized in terms of Wpc board machine, size, and level of automation. Molds are customizable depending on the final product should look like. We have evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently among China's top 10 extrusion lines for plastic.

We follow strict guidelines for Jiangsu Xinhe for Wpc board machine thickness and material We also provide an inventory of components that are vulnerable In addition to ensuring safety our production lines have a long lifespan with low failure rates and stable reliable production Many of our customers have been using their machines for more then 8 years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy