Boards can be made on a demand basis, but special machines are required in order to quickly make high-quality boards. These are board making machines A thicker than 1/6 inches sized board, is called in wooden linggo; the purpose it for outdoors including building and so on. These machines have various sections which work in union to result high-quality boards. This post speaks about the features, pros and benefits these machines offer.

Reliable - they are very well built. They are engineered to high standards, and such much validate testing went into these parts that they are intended for many years of issue free service.set This in turn imply that companies can rely on these machines to keep making good quality boards without breaking down or facing problems. While businesses count on these machines, they can concentrate far better in serving their buyers.

These board making machines are used for manufacturing boards with the latest technology, providing quality output. The boards meet the right standards due to computers and controls attaching this technology. As boards are being manufactured the machines also have sensors built in to ensure that quality of them meets specified standards. If any problems arise, the sensors are able to adapt and adjust immediately.

With the help of this development in technology, these machines work better and quicker than other old methods. Guys were capable of producing the same size/shape/thickness board consistently. Moreover, technology is capable of significantly reducing waste during the board-making process which makes it a more environmental friendly way and better for companies to save money.

Different companies can have the board making machines customized to suit their different needs. This made it posible to adjust the machines in order for producing boards at different size and shapes, but also out of various materials. From this it can be seen that the custom products are key solutionsto prepare better boards at a lower cost for companies so they don'tspend too much valuable resources during manufacturing.

Businesses are able to cater for their customers by using machines that can be tailored. An example of this is how the machine can be set up to produce a special size that might only one customer or even zero customers need - like if someone needs a different shaped board for project. It helps the companies to be competent and serve different types of markets.

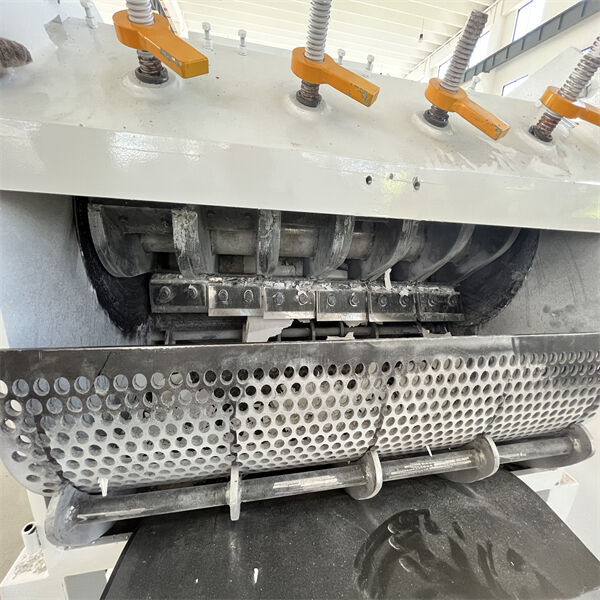

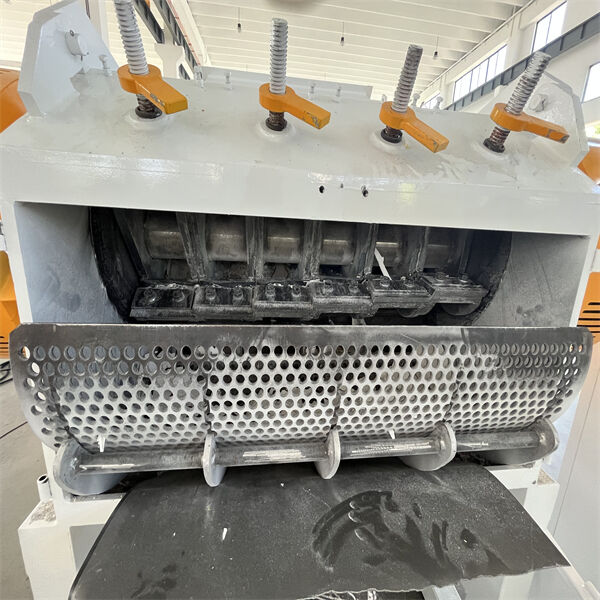

Modern and intelligent designs have been developed for automatcd boarcl making. These designs are so advanced that it allow the machine to form standard size and flat boards time after time. They are also getting optimized to ensure that less material wastage is there whenever a board comes into existence. Companies will ultimately save in materials as they reduce waste and work more effectively.

We customize the configuration of our machines to meet the requirements of our customers factory direct sales premium product quality and a comprehensive after-sales service Our machines last that exceeds 8 years They are highly regarded by clients from Board making machinery Indonesia Saudi Arabia South Africa Bolivia and many other countries

We adhere to strict standards in Jiangsu Xinhe for machine steel Board making machinery and the material We also offer a list of vulnerable components We ensure safety by ensuring that our production lines offer long life span and low failure rates and a stable efficient production A majority of our clients have used their machines for more than eight years

We offer custom Board making machinery that are customized in terms of size, color as well as automation. We can also design molds based on the finished product. We've evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and have now become one of the top 10 Chinese plastic extrusion lines manufacturers.

Pre-Sales: With a combined five years of experience in the field our sales team will recommend to you the best machine configuration. We offer a 24-hour service to our clients and provide video tours of our factory.In-Sales: We can provide videos of production, from raw steel to finished products as well as Board making machinery for the total line.After-Sales Service: Our engineers provide on-site support for a nominal fee and lifetime video technical support, from raw materials through to the final product.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy