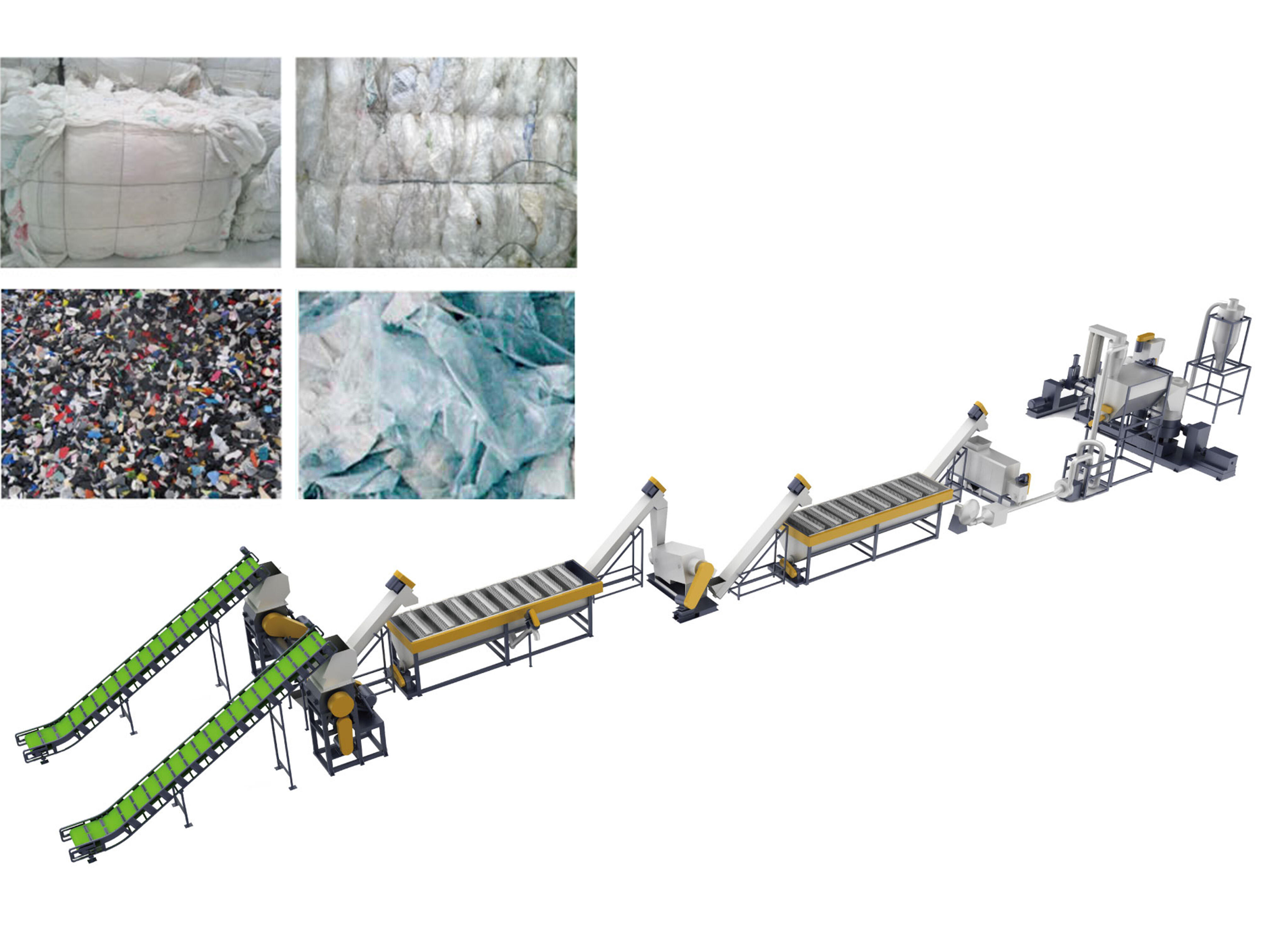

In Thailand, more and more people want to a good quality HDPE pipe making machines. These machines are significant, as they help produce the pipes used for water, gas and other types of materials. The price of these machines can vary widely, according to what features they have and how large they are. For instance, smaller machines may be cheaper than larger, more advanced ones. If you’re interested in purchasing one, it might be helpful to know a little about how much they cost and where you can find them. Our company, Xinhe provides a wide range of HDPE pipe making machines at competitive prices. We believe in quality, dependability and ensuring that our pvc foam board machine manufacturer customers receive value for their money.

It is not difficult to locate wholesale HDPE pipe making machines in Thailand. Online is really the best place to start for most people. Websites such as Alibaba or local Thai business directories frequently have ads for manufacturers and suppliers. It’s easy for you to compare prices and features. You may want to consider trade shows or industrial fairs in Thailand! These events often feature new machines, and give the opportunity to speak directly with company representatives. Having that face-to-face interaction really helps to understand the machines. Additionally, local machine shops or suppliers could have what you need for a good price. And don’t forget to ask about the warranty and after-sale services. You do want to get a sense of how the company, as with Xinhe, will back you up after you have made your purchase. That ought to help you feel good about your purchase. You may also want to network with other pvc foam board manufacturing machine businesses that operate these machines. And they’ll probably be able to give you feedback and direct you to trustworthy sources. Being well connected could play an important role in the manufacturing business. But prices can change depending on where you are, so a quick look-up of the price range is a good idea.

When you want to buy hdpe pipe making machines in bulk, be sure that you look very closely at prices. First, there is the matter of the quality of the machines. Buying a cheaper machine may save you money in the short term but you are likely to pay for it with maintenance fees later on. You will also want to consider the details of each machine. Some rigs can provide advanced options when it comes to saving time and money during production. Such features might result in pricier models, but they might also be worth it if you plan to keep your cooler forever. The other thing to consider is the entire cost of ownership. This includes not just the cost to buy, but anything related to installation, training and maintenance. Firms like Xinhe will often offer packages that come with these, instead of you having to budget for them. It’s also wise to get quotes from several suppliers. This takes the guesswork of what’s available in the market, and allows you to negotiate a better deal. And be sure to look at reviews and pvc foam board machine testimonials from other customers. Their feedbacks can tell you how good the machines work and how about the machine supplier. In the end, you’ll benefit by spending time comparing prices and features to make an intelligent purchase for your business.

HDPE pipe making machines Some problems that people face when using HDPE pipe making machines. One problem that most other coffee makers have to face is becoming jammed. This can occur if the plastic pellets are not fed into the machine properly. To prevent this from happening, the entire feeding system should be checked just before you start the machine. The pellets not sliding well will result in blockage. Temperature settings could be another issue. If the machine is too hot or cold, the resulting pipes may not be sufficiently strong. It is important to stick to temperature recommendations provided by the machine’s manufacturer, Xinhe said. Regular maintenance is also key. Regular machine cleaning and worn part inspections are the operators responsibilities. If any one of them is broken, you should change it so as to not have bigger problems. Sometimes it is due to a lower quality of the raw materials as well. Weak pipes: Older, low quality HDPE may become weak during the manufacturing pvc foam board making machine process. Make sure to use good-quality materials in order that the pipes are strong. Finally, operator training is imperative. They should be trained in how to use the machine appropriately to avoid accidents and mistakes. Through learning these common problems and solutions, users can better operate their HDPE pipe making machines to make high quality pipes.

It's very essential that you make the most efficient use of your HDPE pipe making machine in order to end up with excellent results. One way to achieve this is by ensuring that the machine’s set-up is correct at start of production. You will also want to ensure the settings for speed temperature and pressure match the type of pipe you are trying to make. A Xinhe machine, for example, routinely comes with specific settings for the kind of pipe. Another advice is having a tidy workspace. When everything has a home, operators can work more quickly and spend less time looking for tools and materials. You should also get your workers good training. They work more efficiently if they know how to operate the machine. Another is to regularly maintain and that's a big key, too. By routinely inspecting the machine for damage, you fix little problems before they have a chance to turn into big ones. This can eliminate long downtime in which the machine is down. You might also think of using technology to monitor production. Many machines today are linkable with computers that can be used to track production rates and quality. This way, you can make sure everything’s still working properly. Finally, consider the layout of your factory. If you are an HDPE pipe making machine manufacturer and your machine is near the area of storage for raw materials finished products, this can be convenient to save time and make everything faster. You also should ensure that your HDPE pipe making machine is in its optimal condition by using these tips to save on time and money.

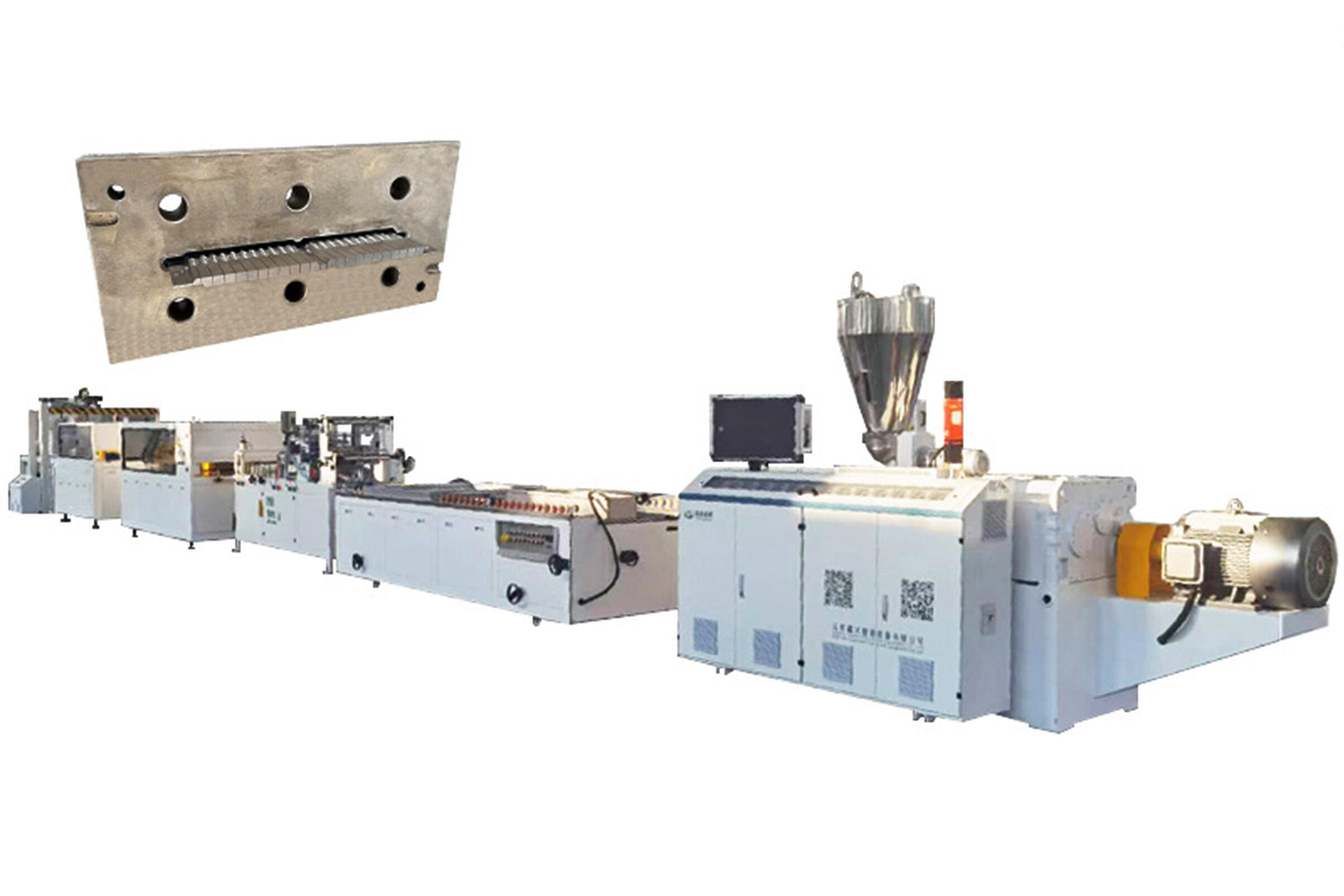

With over 12 years of experience in Hdpe pipe making machine price Thailand, we offer machines that can be customized in terms of color, size, and even automation levels. We can also customize molds based on the finished product. We've evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently one of China's top 10 extrusion lines made of plastic.

Our machines are arranged to meet the requirements of the client We provide direct sales from the factory premium products and an extensive after-sales service Our machines have a lifespan that exceeds 8 years They are well-received from customers from Vietnam Indonesia Hdpe pipe making machine price Thailand South Africa Bolivia and many other countries

Pre-Sales: Our sales staff, with over Hdpe pipe making machine price Thailand of experience, will recommend the best machine configuration for you. We provide 7*24h service to our clients and provide videos of the factory.In-Sales: Our videos demonstrate the manufacturing process starting from raw steel through to finished products.After-Sales Services: Our engineers offer services on-site at cost and lifelong technical support via video starting from raw materials until the completed product.

At Jiangsu Xinhe we adhere to stringent standards regarding the dimensions and materials of machine steel We also provide the most areas that are at risk The production lines we use are built to be safe with an extended life-span low failure rate and a steady reliable production A Hdpe pipe making machine price Thailand of our clients have had their machines for more then 8 years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy