Written by Anne Lewis Do you want to know about an awesome engine that makes food and plastic? A twin screw extruder! Learn more about how it is done, and what makes it so unique!

The twin screw extruder is an incredible device that uses raw materials to produce end products. It takes things that are not in the form we need them (egm flour, or plastic pellets) and makes it in a form where we can eat those products or play ball with eg our Rugby World Cup ball. It is fantastic for making a variety of food, such as your go-to breakfast cereal or delicious pasta. It can even produce plastic items, such as vibrant playthings or practical containers. That is why this Tool works perfectly and you can rely on it to do a great job every time you use. It is because of this that my confidence lies in the build-not something I have experienced as much with other flashlights, and a very important element when you need to start mass-producing products on an assembly line!

You get something extruded means you are squeezing them through a small hole so that they have specific shape and size. Think of a toothpaste that when you squeeze it, the paste comes out in an exact pattern. Twin screw extruder for products are the same every time is really a great advantage. This technology utilises two screws that rotate in counter direction, i.e., twin screw. This particular architecture allows for a very thorough mixing of the raw materials, so that when they come out from the machine all are exactly as well++ tasting. Essential to ensuring your products are the perfect every time! I mean like, if you were making cookies or something wouldnt all the damn cookies taste good?

Little hic-kick ups can happen while you are producing food, or plastic. If they are of a thick material which is hard to mix then no. Picture stirring up some very heavy batter — it would be much more difficult than Far easier to stir something that is smooth. Alternatively, the materials could heat up too much and begin to burn or melt—similar how ice cream melts on a hot day. The beauty of a twin screw extruder is that it can learn to compensate for these issues. Screws can go faster or slower, temperature variation influences the mixture to be cooler of warmer and we could still move some materials in order to help the homogenization. With this adaptability you are able to overcome any challenges the process seems fit!

Throughput rates are a just fancy way to describe how much of something you can produce in x amount of time. A twin screw extruder can help you turn out a lot of product in no time. The Reason Why (It has two screws that can spin fast, like how you turn ingredients with a whisk really quickly). It helps a lot to push the raw material in very fast so you can make more of them faster. Think of it this way: It is like when you are making cookies for a ton of people and they need to be done soon! Well, the great part is that because the products are so consistent and even better lucky for me! Which also means, each cookie or toy you bake/ create is as good as the last because…

Conclusion: The twin screw extruder used for melting and mixing polymers. Think of polymers as long chains and monomers are their tiny cells so that can be further understood with an illustration. By melting and combining various polymers, a great deal of plastics can be manufactured. Or, caveats apply and the products won't be identical or will perform as designed; broken down further — you bake a cake using an ingredient from recipe A in both halves of your split test but then didn't actually follow instructions to add eggs so guess what happens when it goes into oven?! When the answer lies with a twin screw extruder. It does a great job when you are melting polymers and mixing, which is key to making products that have consistent appearance and performance. This precision is invaluable to getting everything just the way you like!

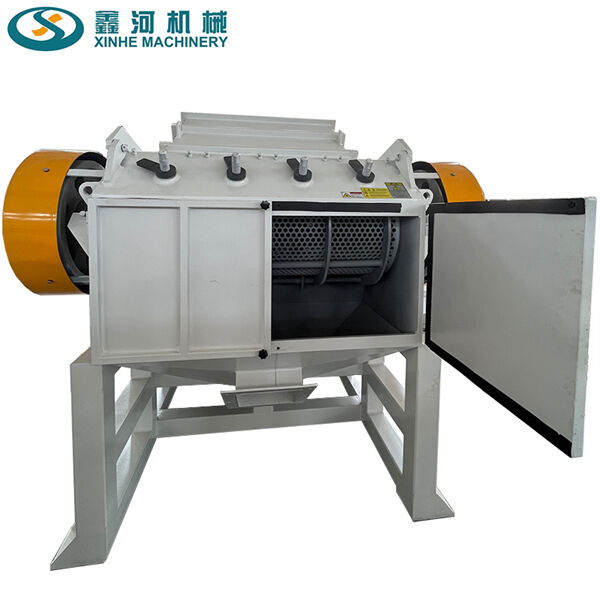

We customize the configuration of our machines to meet the requirements of our customers factory direct sales premium product quality and a comprehensive after-sales service Our machines last that exceeds 8 years They are highly regarded by clients from Extruder twin screw Indonesia Saudi Arabia South Africa Bolivia and many other countries

We adhere to strict standards in Jiangsu Xinhe for machine steel Extruder twin screw and the material We also offer a list of vulnerable components We ensure safety by ensuring that our production lines offer long life span and low failure rates and a stable efficient production A majority of our clients have used their machines for more than eight years

Extruder twin screw: With over five years of industry experience Our sales team will be able to recommend the right machine configuration. We offer 24 hours of service to our customers. We also provide video tours of our factory.In-Sales: Our video clips show the manufacturing process starting from raw steel all the way to finished products.After-Sales Services: Our engineers provide on-site services for a fee and lifelong technical support via video starting from raw materials until the final product.

With 12 years of experience in plastic extrusion, we offer machines that can be customized in terms of Extruder twin screw, size, and level of automation. Molds are customizable depending on the final product should look like. We have evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently among China's top 10 extrusion lines for plastic.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy