PVC is a kind of plastic which is found in so many things we use every day. It is also a building material used in the production of pipes, toys and clothing. So, Its first and foremost step to convert PVC into powder form than we can make a solution with it. It is a PVC powder making machine which helps you with that.

PVC powder making machine is a kind of equipment for recycling PVC. It is a versatile machine with many advantages. At first, it is helping to for creating the powder more fine. This is, that the end of trial powder will be uniform in quality and purity as it were previously situated. This is essential for industrial manufacturers producing PVC products since they need powder consistency that should not be different.

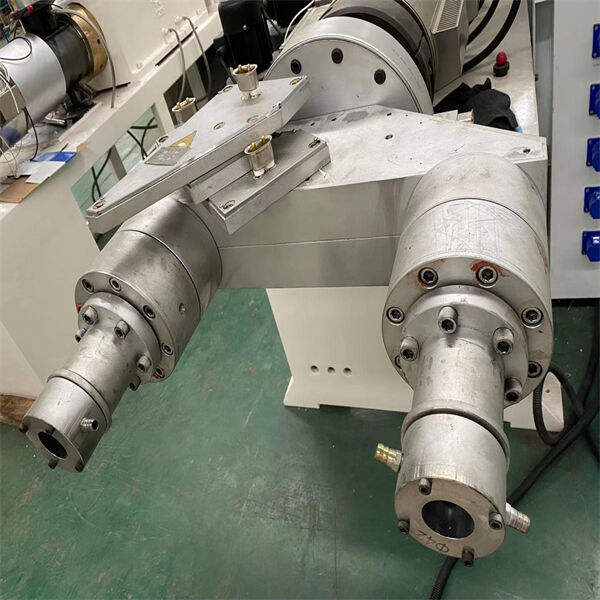

Well, then comes a question how the powder making machine do work? Thing crushes PVC into tiny bits The edges on those things were so sharp, and they could be rapidly spinning in a way that basically turned any PVC into almost nothing. These are then crushed in between the screens to powder and separate bigger pieces from smaller ones. The machine could also be set to the requested sizes of powders by any manufacturers has been made for their applications.

Manufacturers that use PVC powder in their operations go through massive supply volumes of the ingredient to help make sure they have enough on hand for production. So they want a lot of powder made and quickly This is where new age machines can be of utmost help too. They are pretty much self-serving machines to their own advantage and help automate every possible thing at the process end. This not only reduces the time needed but also removes workers which can make this process some what profitable.

There are all kinds of PVC powder making machines in the market, and they come in sizes ranging from some as large as a room to ones not seemingly larger than an oven. Some of the machines are so small that they can fit on a table or lab bench, some others require whole space for manufacturing as these can be massive sizes. Actually, the size of any equipment is strictly based on how much powder has to be made and some special requirements from manufecturer.

Besides this, there are different designs for these machines. Some of this equipment has a spinning bit, referred to as (the)rotor(s) if you want expand the convention shorter way for shredding pvc faster and more efficient in many machines. Some machines use water-cooled grinding wheels to prevent flash so there may not be sparks. Air conditioned may also be provided on some. After all, it's really manufacturer dependent and whatever the manufacturer want to use in their production.

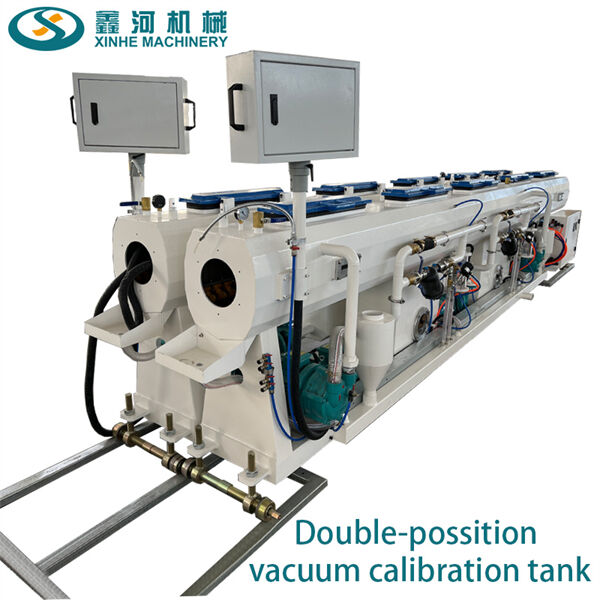

This awesome technology has appeared, dominating the production of PVC powder for years. Faster, more efficient PVC powder production machines are currently being tested. There are few noticeable differences between automated and manual powder machine the major among them is these use computer control systems along with specific-cooling that helps to enhance process of manufacturing a better powdered material. That enables manufacturers to produce a higher quality powders in less time.

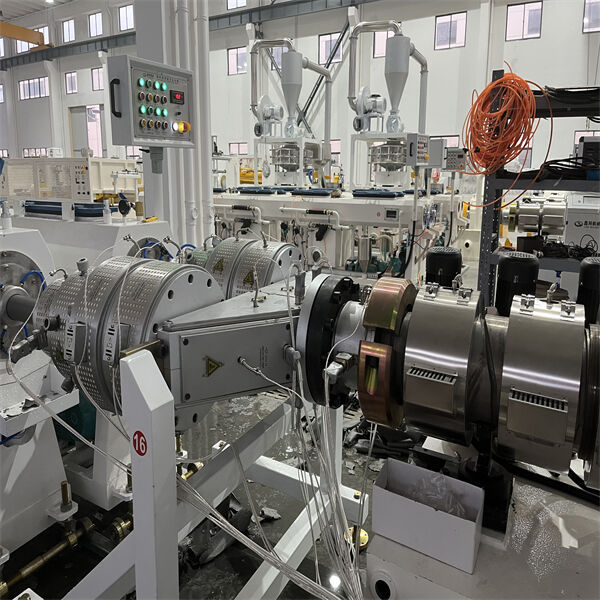

With 12 years of experience in plastic extrusion, we offer machines that can be customized in terms of Pvc powder making machine, size, and level of automation. Molds are customizable depending on the final product should look like. We have evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently among China's top 10 extrusion lines for plastic.

We adhere to strict standards in Jiangsu Xinhe for machine steel Pvc powder making machine and the material We also offer a list of vulnerable components We ensure safety by ensuring that our production lines offer long life span and low failure rates and a stable efficient production A majority of our clients have used their machines for more than eight years

We Pvc powder making machine the machine configuration to the specific needs of our customers We also provide factory direct sales premium product quality as well as a complete after-sales support Our machines are adored by our customers in Vietnam as well as Indonesia Additionally they enjoy a long lifespan lasting for more than 8 years

Pre-Sales: Our sales team with more than five years of experience, will recommend the most suitable machine configuration for you. We offer customer support 24 hours a day and factory tours with video.In-Sales: Our videos illustrate the manufacturing process starting from raw steel to the finished products.After-Sales: Our engineers offer on-site support for a Pvc powder making machine and lifetime video technical support starting from raw materials through to the final product.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy