Hey kids! Do you even realise what the toys that you play with, and those vibrant raincoats of yours as well as all the pipes carrying water in your home are made from? Therefore, it all begins with a certain machine that is known as the PVC making machine. These machines are responsible for producing a vast number of the plastic products we encounter every day.

PVC: Polyvinyl Chloride It is a type of wonderful plastic and it creates countless things The new PVC making machine is one of the most productive tools for these products. These machines will enable factories to manufacture tons of products in a short amount of time, very awesome!

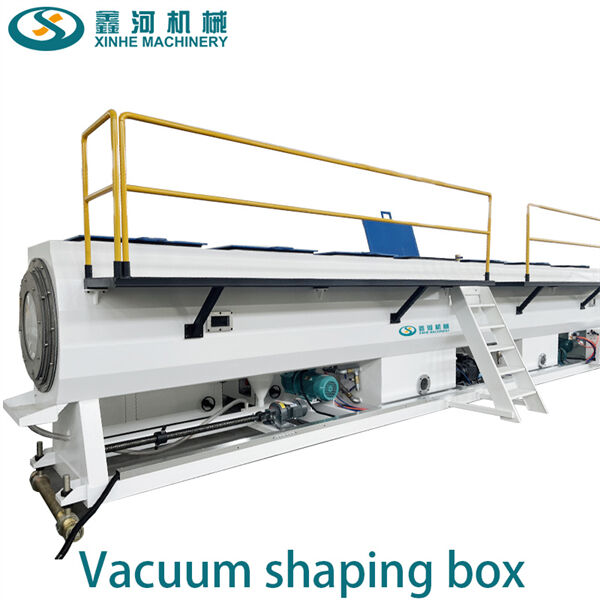

PVC products used to be made by hand. It was 4 years of grinding. Today, however, they use amazing machines in factories to make tons of stuff at once. Using hot air and pressure, the PVC making machine molds a large clump of plastic into shapes. You can also adjust it to make different sizes and shapes,as well thereby making the whole process fast as well as accurate.

Having the feedstock and machinery are great prerequisites for producing PVC products. In reality, without the advanced PVC making machines everything would be very different. This makes the plant more productive and increases its efficiency—the workers produce more of each type of product in less time than they did before. This allows them to adjust faster for customer s requests!!

If you compete with factories, which are looking as hard as possible for the highest quality and best machines. The best PVC making machines make a big difference in how many products can be created fast and efficiently. They are designed according to the latest technological know-how and perform better and longer. It allows factories to produce high-quality goods more quickly and ensure everything they make is built to last.

When creating PVC products, innovation is key. Here, newer machines can bring out patterns and designs that were very difficult to manufacture back then. For instance, machines can create elaborate and perfect patterns that give each PVC product an edge ensuring it looks one-of-a-kind. Some Thermoforming can even reprocess the old products of PVC into the new one which is very good for an environment and used in waste reduction.

At Jiangsu Xinhe we adhere to stringent standards regarding the thickness and materials of machine steel and provide the most areas that are at risk Pvc making machine safety measures our production lines offer long life span with low failure rates and a stable efficient production Many of our customers have been using their machines for more then 8 years

We offer customized machines in terms of size, color and even automation. Molds can be customized depending on the product that is produced. Pvc making machine from Zhangjiagang Xinhe Machinery to Jiangsu Xinhe Intelligent Equipment Co., Ltd., we have grown to become one of China's top 10 extrusion line producers.

Pre-Sales: Our sales staff with more than five years of experience, will Pvc making machine the best machine configuration for you. We provide 24 hour service to our clients and offer video tours of the factory.In-Sales: We can provide videos of production, from raw steel to the finished product as well as videos of production on the total line.After-Sales Service: Our engineers offer on-site support for cost and lifelong technical support via video from raw materials to the finished product.

We tailor the machine Pvc making machine to the specific needs of our customers We also provide factory direct sales high product quality and comprehensive after-sales support Our machines are highly regarded by our clients in Vietnam as well as Indonesia Additionally they have longevity that lasts longer than eight years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy