A special kind of plastics called pvc can be used to manufacture a large variety of all you need with PVC MACHINE, as well as the Xinhe's plastic sheet extrusion machine price. Because of its durability and long life, this plastic is an economical material that can be used in many types of products. When you are going to make something from PVC a must is powerful, reliable machines capable of doing the work hence Machine PVC technology till your last breath.

A variety of different machines have been built to help you create items made out of PVC. Thankfully over the past few years new and better machines have been developed that both improve upon this process as well one step ahead of it. Modern-day unicorns, harnessing the power of technology for people to mass manufacture more and new PVC products with. PVC is a thermoplastic, and so it can be reheated to the point that you could mold this bender again. As a result, PVC items can be produced much faster. with considerably lower expenses. What is more, new machines are less error-prone and they also drive waste lower or even save you some money. So these appliances make things simpler and also benefit the corporates by cost saving.

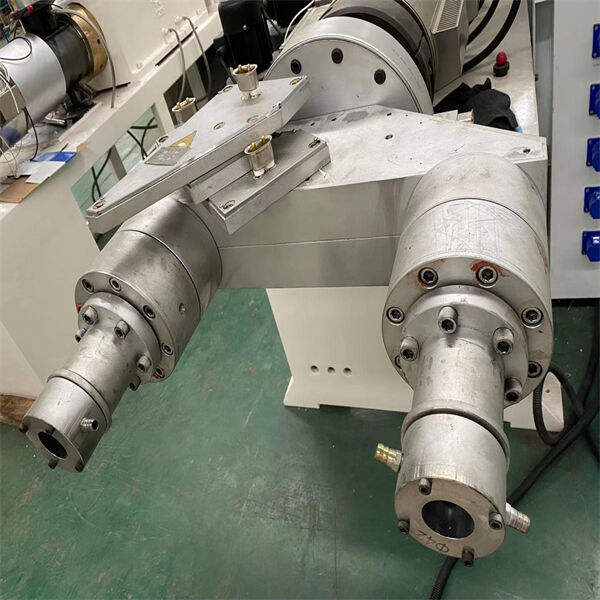

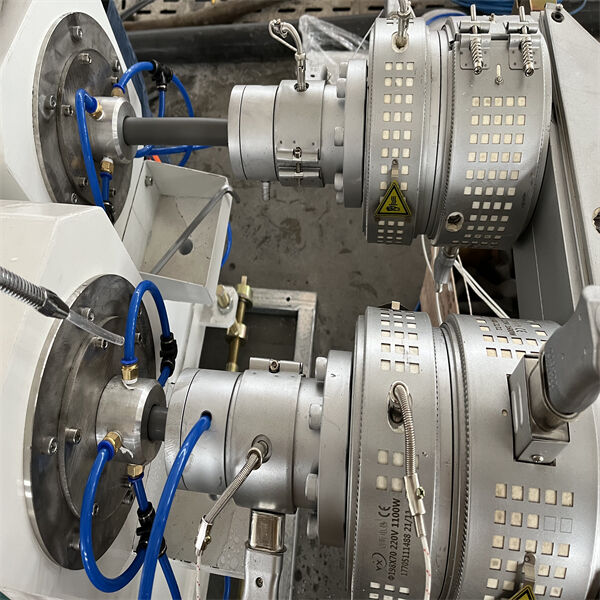

In manufacturing PVC items, one of the key things to consider is a process that we call Extrusion, same with the door frame making machine manufacturer from Xinhe. Softener: This is where the PVC material reshapes once it has turned liquid due to melting. Wonderful machines handle this process rapidly and precisely, enabling an end result that appears just as you wished it would; a win-win. The machines are adjusted in such a way that it will melt the PVC at just right temperature so that this process should be perfect every time. They also can melt PVC and shape it toughness into any form we want like pipes, sheets even fun toys. This is why PVC can be found in a variety of industries.

Automation is when machines do work with less help by humans, identical to Xinhe's product pvc pipe production line. PVC machines are much more easier to use than doing it manually, yet many potential shop owners or workers want everything easy and fast. The best thing is, with the aid of these smart machines most of this heavy labor can be done on its automatically given null possibility for human failure. The humble PVC familiar to everyone through its use for plumbing pipes can be mixed with appropriate additives to produce hose and cable coverings, outdoor rubber boots etc. This increased productivity leads to an increase in quantity of the products being made within a lesser time which consequently could make high profits for a company.

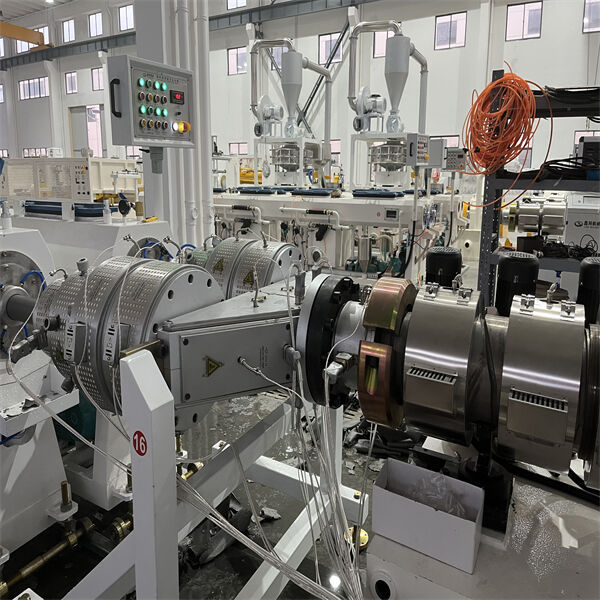

The term cutting edge is used to characterize the new and most advanced of something, same with the pvc foam board manufacturing machine supplied by Xinhe. Due by the latest machines of today available for individuals, PVC products are being produced in a well-ordered way and with splendid nature as uncommonly some time recently. These automated machines of present days maintain the PVC in its right shape, and temperature whenever needed They are very high speed and capable of operating up to 24 hours with brief rest requirement which enables producing several PU or PVC products in much quicker time. This is especially good for industrial mass production.

Streamlining: The word used for making something work better and more efficiently in order to save you time, money or both plain and Simple, identical to Xinhe's product pvc pipe extrusion machine. This new technology makes PVC machining easier than ever With Machine Technology the machines are engineered to work in perfect sync which means increased speed and productivity throughout. This enables quicker and less error-prone creation of PVC products, which impacts the quality to follow as well. Second It will make industries profitable as they can reduce their BOM in one to one interaction for each and every item being made.

Our machines are arranged to meet the requirements of the client We provide direct sales from the factory premium products and an extensive after-sales service Our machines have a lifespan that exceeds 8 years They are well-received from customers from Vietnam Indonesia Machine pvc South Africa Bolivia and many other countries

We offer customized machines in terms of size, color and automation. Molds are customizable in accordance with what the final product is expected to look like. We've evolved from Machine pvc and have become one of the top 10 Chinese extrusion lines made of plastic.

We follow strict guidelines for Jiangsu Xinhe for Machine pvc thickness and material We also provide an inventory of components that are vulnerable In addition to ensuring safety our production lines have a long lifespan with low failure rates and stable reliable production Many of our customers have been using their machines for more then 8 years

Pre-Sales: Our sales staff, with over 5 years of experience, will recommend the appropriate machine configuration for you. We provide 24 hour customer support as well as video factory tours.In-Sales: Our videos demonstrate the manufacturing process starting from Machine pvc to the finished products.After-Sales Service: Our engineers provide on-site service for a fee and offer lifelong video technical support starting from raw materials to final products.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy