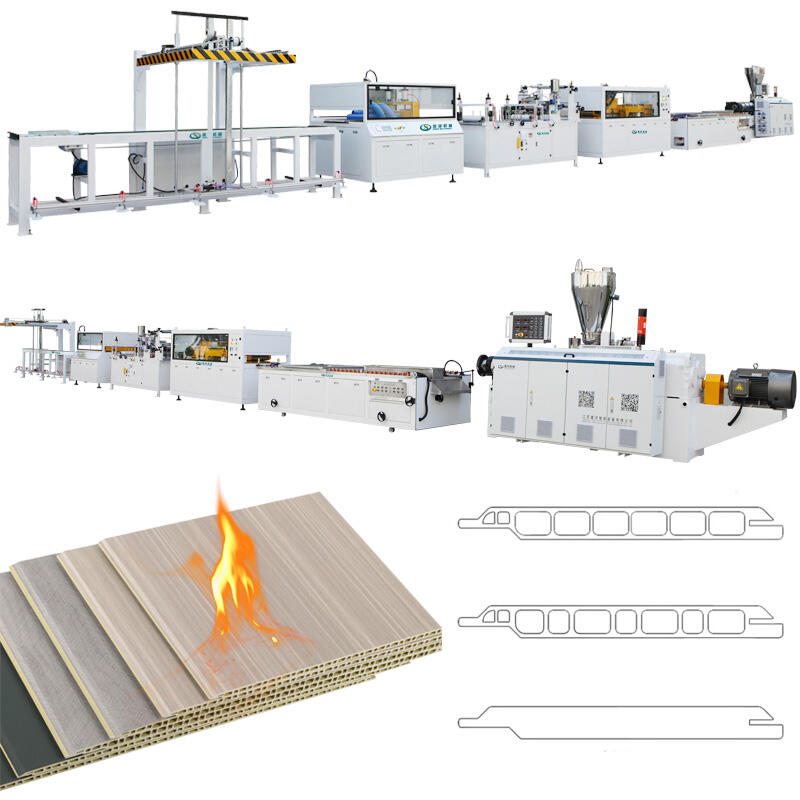

The customized PVC WPC plastic wall panel indoor decoration production lines of Xinhe Machinery have the 7m/min and 4m/min with the core difference being their matching molds. These variations contribute to the differences in the efficiency of production, the establishment of stability, and applicability, which suits the needs of different customers without compromising the quality of the products.

Mold design for speed adaptation

Xinhe has specific molds in the two production lines. The 7m/min line mold has a line with an optimized runner structure allowing smoother and faster material flow to suit the high-speed extrusion. By contrast, the 4m/min line mold has a more elegant runner design, aimed at stable material flow to fit the low-speed operation, which ensures alignment of each mold with its line speed.

Production efficiency and output

The 7m/min line that has its own mold produces more efficiently. It is able to manufacture additional PVC wallboards within the same period, thus it suits the customers with big orders. The 4m/min line having the appropriate mold provides moderate production, which is adequate to both the customers who have fewer batch production requirements or those who are interested in a relatively slow increase of production.

Material flow and forming stability

To ensure the steady flow of material even at high speed, the mold designed by Xinhe to support the 7m/min line flow eliminates any problems such as non-even thickness of wallboard due to high-speed extrusion. The mold of the 4m/min line, in its turn, increases forming stability at reduced speed, decreasing the number of small flaws in final production and guaranteeing the uniformity of quality, as slower speed in combination with the shape of the mold can allow shaping it more accurately.

Adaptability to customer scenarios

Xinhe suggests the line of 7m/min with its particular shape to the customers who want to supply the market as fast as they can or have large orders, which enables the customers to capture the business opportunities in a short period of time. The line with mold of 4m/min is more appropriate to customers with niche markets or insufficient initial production scale, who need the balance between the cost and quality of production.

To conclude, Xinhe Machinery is distinguished by the 7m/min and 4m/min PVC wallboard production lines, which are mostly characterized by customized mold designs. The various types of line and mold combinations correspond to the individual customer requirements in terms of efficiency, output and application conditions, and maintain the standards of quality products of Xinhe.

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ