When the rate of output of a finished product on a Wood-Plastic Composite (WPC) door production line is 0.8 meters per minute we know that this is a very good manufacturing efficiency benchmark and we understand how difficult it would be. We know that this level of achieving is made possible by a narrow margin of high-level machines, highly skilled assistants and strict maintenance of the processes. At Jiangsu Xinhe Intelligent Equipment Co., Ltd., we deal with providing high-tech plastic machinery solutions, thus, we not only make such level of productivity possible, but also repeatable across the board.

High-Quality Machines and Molds: Xinhe machinery

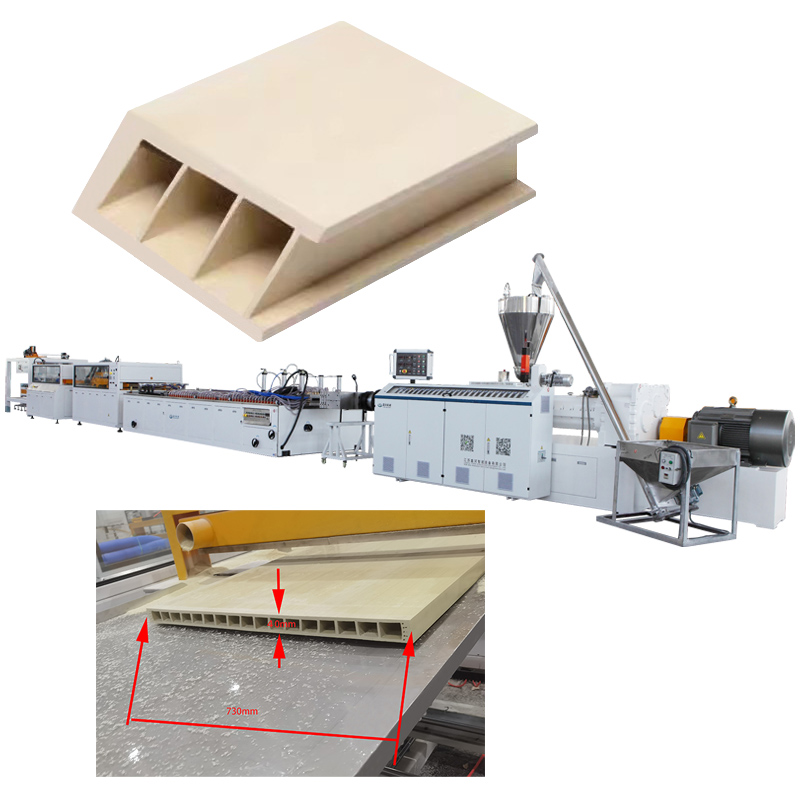

When we observe any well-designed WPC door production line we are well aware that the extrusion system is in the centre of the circle. Our twin-screw extruders are designed to be high-output and long-lasting, and are designed specifically to available WPC formulations to mix homogenously and be precise in regulable melting temperature. This enables us to have a product flow that is smooth, homogeneous and thus necessary in maintaining dimensional accuracy as well as high quality of surface at higher speeds of production.

Meanwhile, we equally emphasize precision molds and the calibration units. The molds used by Xinhe to make door profile are designed to guarantee uniformity of shape, density and vast structural integrity. With our efficient vacuum calibration and forming systems in combination with these molds we give the possibility of rapid shaping and cooling without loss of strength or surface finish. The output we provide is stable extrusion process which can run continuously with 0.8 m/min with minimal waste and downtime.

Skilled Engineering Technical Support

We feel performance lies on expertise, even with state of the art equipment. It is with this reason that our engineering personnel offer comprehensive technical support beginning with installation of the line and optimization of the processes up until the complete training of the operators. We hand over our work to customers to hone screw speed, temperatures and puller limits to suit exact material recipes and door sizes.

In addition to installation, we also provide real-time troubleshooting and preventive maintenance services to our clients. We are able to find out and correct problems like uneven extrusion or profile deformation prior to occurrence in production. Through Xinhe we will be able to make manufacturers run, but run intelligently and much more dependably.

Stable Cooling Water System

In WPC extrusion we are aware that the cooling is the process in which the extrusion solidifies to become the final form of its usability. We believe that a stable and efficient cooling water system is necessary in order to have a consistent achievement of 0.8 m/min. This is why we have production lines with an added feature of high multi-stage cooling tanks with an accuracy of temperature control at a range of ±1 0 C. We develop these systems to cool down the heat slowly and evenly, eliminating stress, part bending, and flaws on the surface.

We use a regular procedure of cooling to maintain profile shape and mechanical characteristics at increased line speeds. In this connection, our systems have also been equipped with effective water circulation and chilling equipment and, therefore, we have been able to save on energy, whilst ensuring an impressive system stability in our processes.

Why Choose Xinhe for Your WPC Door Production?

One of the Jiangsu Xinhe manufacturing sites is the integration of patented extrusion technology, innovative mold design, and holistic engineering support, to provide a complete solution to the production of WPC doors. We are honored that our equipment is relied upon all over the world to be of good quality and performance allowing the manufacturer to produce more, improve and profit the quality of their product, and expand their market share.

It is either you are manufacturing WPC doors or producing profiles or sheets, then we have the technology to offer the knowledge to produce on the level you desire. Using Xinhe machinery we manage to transform a desired rate of 0.8 m/min of a finished product to a reliable production level.

You are willing to streamline your WPC door manufacturing, then we want you to call Jiangsu Xinhe Intelligent Equipment Co., Ltd and see how our highly developed extrusion lines and professional technical service can make your long term success.

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ