We are fully aware that in the cut-throat PVC ceiling panel production industry, we should judge that the only standard of success is speed in a compromise fashion. Achieving a stable production speed exceeding 9 meters per minute is also a major technological and functional advancement that will directly influence production, productivity and profitability. We can definitely state that we did not accidentally reach such amazing performance at Jiangsu Xinhe Intelligent Equipment Co., Ltd, we have reached such excellence with a carefully designed system which is founded on three solid pillars.

Experience Accumulated from Hundreds of Ceiling Production Lines Annually

Starting on the factory floor, when we discuss theory and practice, is always the way to begin. We believe that the greatest strength that we possess is the incomparable amount of practical real-life data and optimization which is acquired through the installation and maintenance of hundreds of complete PVC ceiling production lines every year in different markets around the world. Since we are running at this scale we are constantly facing and remedying some really unimaginable production issues, their variability in raw materials, environmental and operational.

Every project contributes to a living database of best parameters, repeat bottlenecks and solutions to problems. This constant feedback mechanism gives us the ability to pre-engineer reliability and speed into every new line we build. We do not just sell machines we consult the experience and battle-tested process know-how and ensure that our clients can enjoy optimum performance on their first day and by-pass the expensive trial and error stage.

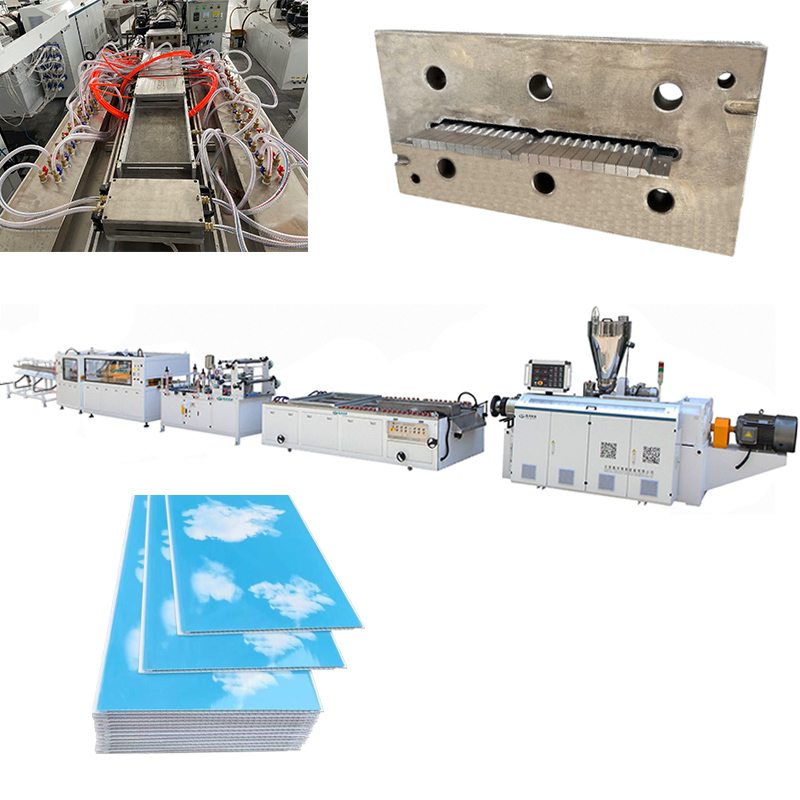

High-Speed Three-Section Mold Configuration

When we are targeting 9 meters per minute, we see the very core of the process in the consistency in extrusion and forming. The real difference is in the proprietary high-speed three-section mold configuration that Xinhe uses. This new system, unlike the traditional models, has been developed to have a perfect control of the molten PVC flow and formation through three optimized stages.

First Section (Distribution): We guarantee material flow that is even through the width of the complete profile of the ceiling without any weak points or density differences that may lead to breakage during high speed.

Second Section (Compression): We use a high degree of control in imparting pressure on the compression stage to ensure that the material has been forced to consolidate, forcing the air out of any gaps and to achieve excellent physical strength and surface integrity, which in turn are desired prior to fixing the last shape.

Third Section (Forming & Calibration): During forming and calibration, the profile is dimensioned and embossed with an embossed surface texture using a very efficient multi-vacuum calibration unit that has a design to achieve high heat transfer. We freeze dimensional stability whilst the material is traveling at a high speed.

In such three-step design, we allow faster cooling and shaping and yet keep quality of the surface and hardware to the highest, and so long-run high-speed production is not only feasible but also steadily constant.

Practical Raw Material Formulation

Regarding our experience, we do realize that even the most developed production line in the whole world cannot work at high speed with the materials that are not the best. We are convinced that speed is closely associated with formulation. Based on our long experience in the application, we assist our clients with feasible and economical casts to ensure high speed doing away with raw material formulations.

Our technical services involve advice on the optimal combination of PVC resin, stabilizers, lubricants (internal and external) and modifiers. The objective is to obtain a compound that has:

Excellent thermal stability outstanding thermal stability to withstand shear heat produced during the high extrusion rates.

Optimal flow characteristics (rheology) to smoothly pass through the high-speed mold.

Rapid fusion and gelation properties to set quickly in the calibrator.

Superior impact strength and surface finish on the finished product.

We can see an interaction of the machine and the material such that that can be required to prevent surging and degradation of the most common extrusion speed limits.

Conclusion: A Symphony of Speed and Stability

At Jiangsu Xinhe, it is never about pushing one single component beyond its capacity, which is over 9 meters per minute. We do so through absolute balance between perfect harmony of deep practical experience, patented mechanical design, and applied material science. Our entire extruders of PVC ceiling include both high-output twin-screw extruders and high-output, precision mold, high-speed calibrators, and pullers are designed as entire systems to accomplish this very specialty.

In this way, manufacturers are enabled to dominate their markets with unmatched productivity, consistent high quality, and superior return on investment. We refer to this as the Xinhe advantage; the ability to take the problem of extreme speed and convert it into an acceptable, daily production norm.

With your readiness to proceed we are offering you to make a boost in your production of PVC ceiling. Call Jiangsu Xinhe Intelligent Equipment today and we will demonstrate to you how our traditional technology and experience can transform your manufacturing capacity.

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ