One such massive and important piece of equipment in many factories is a single screw extruder machine. This machine helps in making multiple products such as: plastic pipes, bags and even toys. Particularly in industries where products are manufactured from molten materials. In the machine, a long screw spins around. A plastic material is fed into the machine and melted by an electrical heating system, which then turns a screw that pushes the hot liquid out of a small end opening in any 3 dimension surface shape.

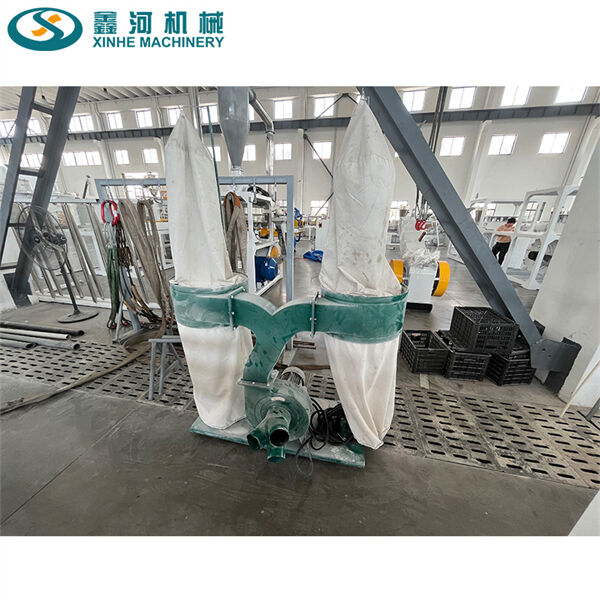

The single screw extruder machine has a feeding system, heating system (drying), and some other... — Published on Medium Feeding system is the first, this addition raw material Processing and then it puts into place that can be plastic pellets or others. Afterward, the heating system starts. It heats the materials with heaters at several positions in this machine. In the case of this 3D printer, that heat is provided by those very same heaters and assures that materials are hot enough to liquefy.

The giant screw inside the machine will start to push all of this forward once its contents get hot enough. The system is called the screw. The screw takes the melted stuff away and stirs it to warm up evenly. This material is heated so that it melts, and afterwards goes to the shaping system. The material that has been melted is placed: molded into the shape at this stage of machine. The machine makes use of different types of molds and tools to produce required shapes as well as sizes. The material is allowed to cool after molding and soon it will be ejected from the machine as a final product.

A single screw extruder machine offers several benefits. The advantage of it is one belt servicing many appliances. This machine helps in producing a wide variety and great number of products within very less time. It can quickly manufacture items such as plastic pipes and bags in less than ten minutes. This ultra-fast speed in production can be a big deal for the factories who has to fulfill many orders very quickly.

If you want products that are the same size and shape, this machine is the best. It gave a consistent look to everything, that ultimately is great for quality control. Moreover, this particular kind of single screw extruder machine is small so it will not eat up that much area in a factory making it also one among the first preference for entities which may perhaps have smaller regions just where machines could sit down on.

The single screw extruder machines are employed in a host of different fields and industries. These machines are used heavily in the polymer industry to produce items such as plastic pipes, bags and toys. Within the food industry, they are used to produce such comestibles as pasta and crispy snacks. Even in the medical area, these machines are crucial because they add produce tubing for IV and essential other tools that doctors need.

On the manufacturing side, consider what kind of products you want to produce in the first place. For example, machines that specialize in one type of object (i.e. pipes) work more efficiently than other such as those used for toys or different products. Also, how automated you want the machine to be. Fully automated machines — able to run autonomously, and machines that require manual operation

Pre-Sales: Our sales staff, with over 5 years of experience, will recommend the appropriate machine configuration for you. We provide 24 hour customer support as well as video factory tours.In-Sales: Our videos demonstrate the manufacturing process starting from Single screw extruder machine to the finished products.After-Sales Service: Our engineers provide on-site service for a fee and offer lifelong video technical support starting from raw materials to final products.

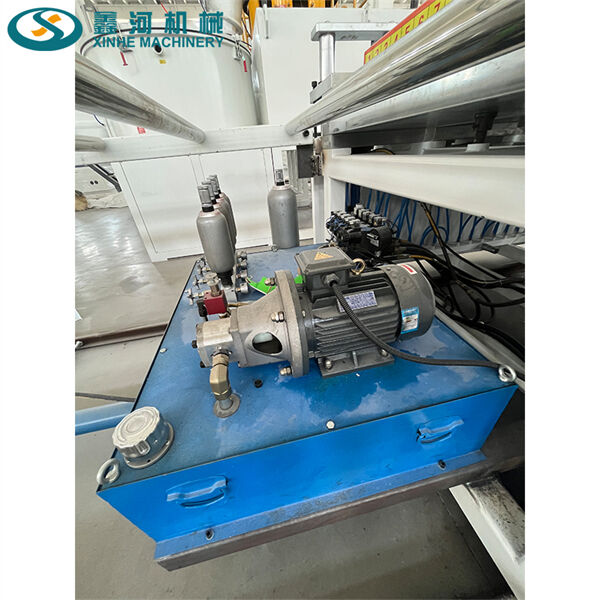

In Jiangsu Xinhe we adhere to strict standards for the material and thickness of machine steel We also provide the most vulnerable parts In addition to ensuring safety our production lines offer long life span as well as Single screw extruder machine rate and reliable stable production A majority of our clients have utilized their machines for more than 8 years

We can Single screw extruder machine customized machines in terms of color, size and even automation. Molds can be customized depending on the product that is produced. We've grown from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and have become one of the top 10 Chinese plastic extrusion lines manufacturers.

Our machines are arranged to meet the needs of the customer We provide direct sales from the factory premium products and an extensive after-sales support Our machines are highly valued by our customers in Vietnam as well as Single screw extruder machine They also have an extended life span which is more than eight years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy