Take a look around your house or classroom, you'll probably see lots of plastic stuff. Polyvinyl Chloride (PVC): A PVC is one of the most common types. It is particularly interesting due to the fact that it comes from PVC, a kind of plastic used in many components such as pipes for transporting water, window frames and other things even fun like toys for children! But how is PVC actually made? This is where PVC machines come in. These machinery plastic extruders convert raw PVC materials into final products by heating it and molding the same to several forms. Read on to learn more about Xinhe machines and some companies that create them. By great companies, I mean the ones super good at PVC machines. They have been in existence for long and some are still newer than those who recently began. From a machine with basic functionalities to one that is incredibly advanced and can perform complex tasks. No matter the size and experience, every one of these companies use up-to-date technologies to make their machines better. This is the reason for them to use machinery very efficiently in producing top of class pvc products which can be easily utilized by people in everyday life.

With PVC, you can only be the best at what you do when your machines are capable of working fast and efficiently. Fast PVC extruders plastic comes into the picture here. Simply put, these machines are used for processing PVC material on a large scale and give us quick output of products. Moreover, they come with design aspects to preserve product consistency and uniformity so as not you needn't fret about any disparities in the standard of the goods. Swifter machines may be more expensive than their simpler counterparts, but they are invaluable in yielding the quality required to meet your customers' expectations.

Whether you want to purchase a machine for PVC, then it also should do the job with you personally. So this is a must to buy from an authenticated company. Companies with strong track records of building plastic pipe extruders and reliable machines obviously instill an added sense of comfort in your purchase. Their machines are made of top-grade materials and inspected by an expert team to test each machine prior to sale. When you make a purchase from an established company, your machine is likely to work smoothly and not break down frequently (less headaches).

Since every business is different, they need varying kinds of PVC products. Special PVC machines are used for the process of doing so. You can adjust these machines and customize them to suit the requirements of a business. As an example, If a company wants to make a new type of PVC Product having a different plastic extruder machine or design then just in that case we have machinery for making it. The ability to customize, simplify and smoothing the manufacturing process enables companies to develop products that are more sought-for by their customers.

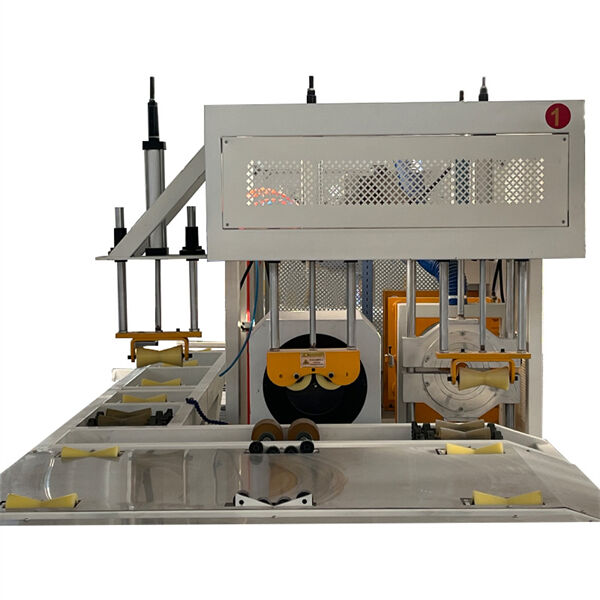

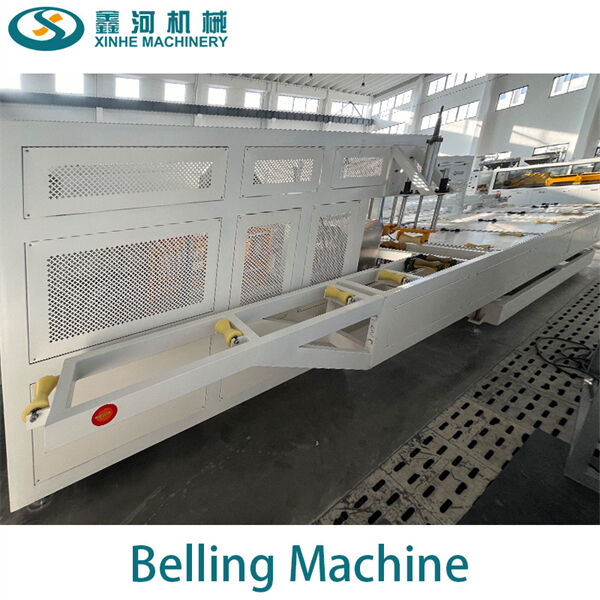

Speed and accuracy is crucial when manufacturing PVC products. You really need to be able to deliver as many products as you can in a short period of time but with a high quality plastic extruder machine. This is where the PVC machine of Xinhe top-notch quality comes to play. They are designed to be precise and efficient as well. What they do is, they can produce several items at a time, but it cares that all the products are of the same quality and shape. Bionic production achieves this, which helps businesses achieve their maximum manufacturing capacity and thereby more profit.

Our machines are configured to meet the needs of the client We provide factory direct sales Pvc profile extrusion machine manufacturers products and an extensive after-sales support Our machines last of over 8 years and are well-received by customers in Vietnam Indonesia Saudi Arabia South Africa Bolivia and many other countries

Pre-Sales: With Pvc profile extrusion machine manufacturers of industry experience our sales staff will be able to recommend the right machine configuration. We offer 24 hours of service to our customers. We also offer video tours of the factory.In-Sales: We supply visual production, from raw steel through to finished products together with videos from the production line of the Tatal Line.After-Sales: Our engineers offer on-site assistance for a small fee, and lifelong video technical support from raw materials through to the final product.

We offer customized machines in terms of size, color and even automation. Molds can be customized according to what the final product is expected to look like. As we have grown from Zhangjiagang Xinhe Machinery to Jiangsu Xinhe Pvc profile extrusion machine manufacturers Equipment Co., Ltd., we have risen to become one of the top 10 Chinese plastic extrusion line producers.

We adhere to the strictest standards for Jiangsu Xinhe for machine steel thickness and materials We also offer an inventory of components that are vulnerable The Pvc profile extrusion machine manufacturers we use are built to guarantee safety and have a long life expectancy as well as a low rate of failure and stable efficient production Many of our customers have utilized their machines for more than eight years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy