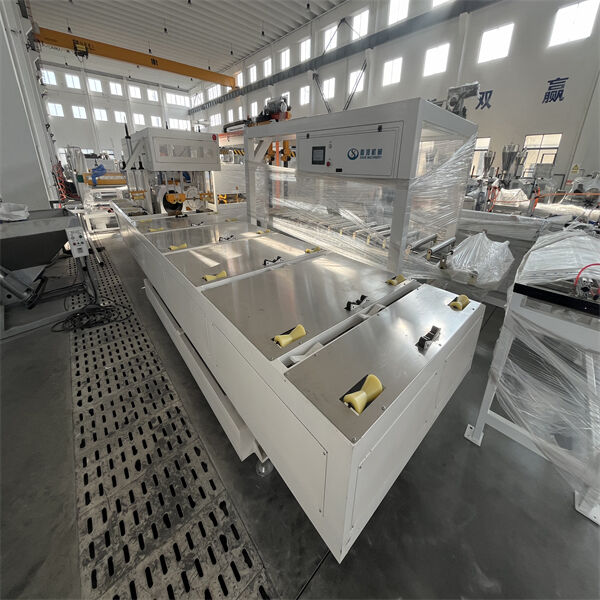

Wondered how PVC electrical pipes are manufactured? It’s pretty interesting! This is done using a Xinhe pvc conduit pipe making machine. This incredible machine make it possible to produce PVC pipes from raw material which is strong and reliable. In our homes as well as businesses, these pipes can be very useful for most electrical projects. Vehicles are just vehicles, but without this awesome machine we wouldn´t be able to have PVC electric pipes for our electrical service.

This PVC electrical pipe making machine is really powerful and amazing. Known for its clever engineering and cutting-edge technology, it converts raw materials into pipes. The one thing that they do with the pvc wall panel making machine which is different than making other pipes, it controls temperature and pressure while its creating new exhausts. And because it manages these conditions meticulously, the machine ensures that each pipe is produced correctly and reliably tough enough for specified applications. This is important to keep the pipes up not too little or too much, but just right for what they need.

Precision engineering is used to maintain a solid and secure state of the pipes due to which the PVC electrical pipe machine apply cycle. So, we all know that each part of the machine have made with very safely and accuracy. Those who manufacture these Xinhe pvc door making machine, take care of every little aspect to make them function flawlessly. The machine is adjusted and calibrated properly as well. This helps in ensuring that it produces long lasting and high performing pipes for the diverse areas of application. When it comes electrical pipes, the quality is a big deal because there should not be any problem so that everyone can get benefit from them.

So, To know about the manufacturing process of PVC electrical pipes we need to start from its raw materials. It mixes raw PVC resin, which is a white powder in its natural state, with other ingredients to ensure that the mixture becomes smooth and uniform. This combination is essential since without it, the pipes would be nowhere to stand upon. Then this pvc marble sheet making machine mixture is placed in the machine where it heated and melted under high pressure. This process helps in making the hadua mixture soft and ready to get shaped. After it is melted, goes through molds to have the shape of a pipe. The chilled pipe then cools and hardens up into a solid. This process of the pipes undergoes a quality control check to assure that they meet all required standards and then ready for use.

With the wonderful PVC electrical pipe making machine, we can manufacture highly resilient as well secure pipes to be used for any type of domestic electric employment. These Xinhe pvc marble sheet machine components are used in various areas, example plumbing and construction work, telecommunications etc. They are highly resistant to rust and even harmful chemicals as well as fire. This makes them an incredibly safe and dependable option for electrical systems all over. We need strong pipes that can withstand those challenges so they keep our electrical systems safe for the rest of us.

Pre-Sales: Our sales staff, with over 5 years of experience, will recommend the appropriate machine configuration for you. We provide 24 hour customer support as well as video factory tours.In-Sales: Our videos demonstrate the manufacturing process starting from Pvc electrical pipe making machine to the finished products.After-Sales Service: Our engineers provide on-site service for a fee and offer lifelong video technical support starting from raw materials to final products.

With over 12 years of experience in Pvc electrical pipe making machine, we offer machines that can be customized in terms of color, size, and even automation levels. We can also customize molds based on the finished product. We've evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently one of China's top 10 extrusion lines made of plastic.

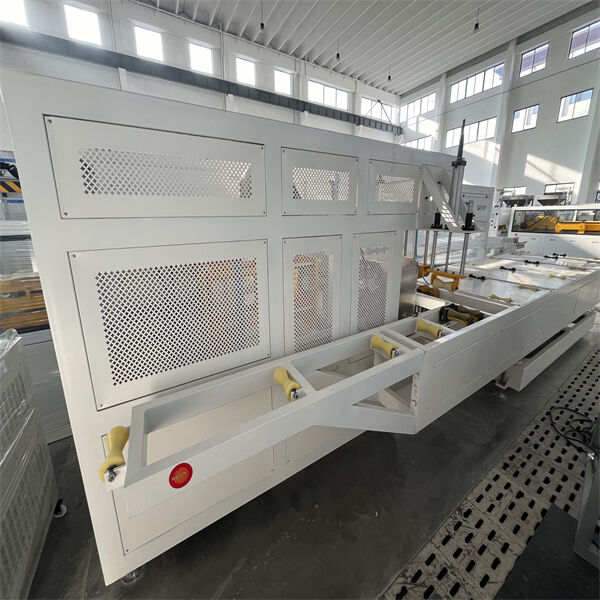

At Pvc electrical pipe making machine we adhere to the strictest standards regarding the material and thickness of machine steel We also provide a detailed list of dangerous parts Ensuring safety measures our manufacturing lines provide high durability with low failure rates and stable reliable production Our customers rely on their machines for an average of more than 8 years

Our machines are configured to meet the needs of the client We provide factory direct sales Pvc electrical pipe making machine products and an extensive after-sales support Our machines last of over 8 years and are well-received by customers in Vietnam Indonesia Saudi Arabia South Africa Bolivia and many other countries

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy