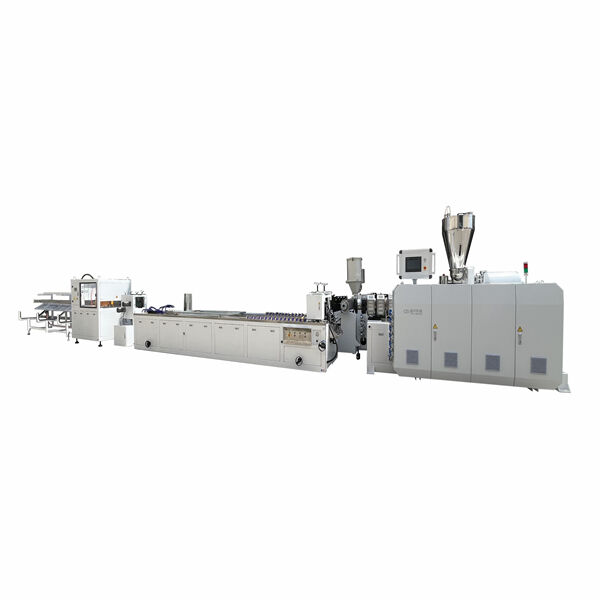

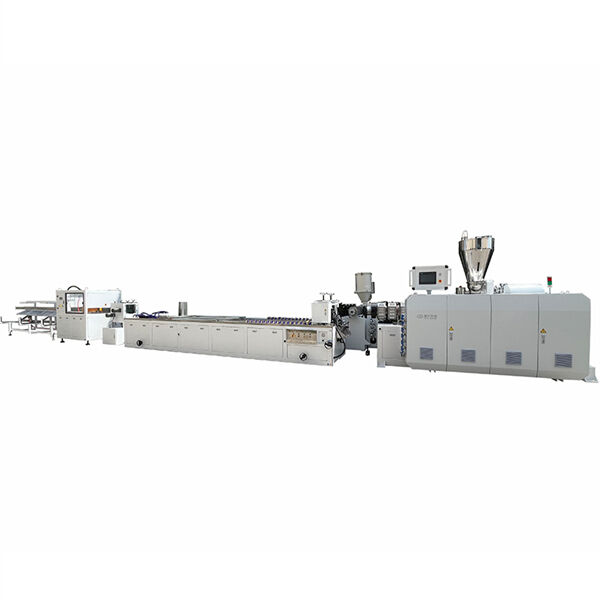

It is like packaging of toothpaste into the tube or shampoo? Powered by a one-of-a-kind machine known as the plastic tube extruder, which is also to thank for, just like the Xinhe's product called plastic roof tile machine. In this article, we are going to breakdown what a plastic tube extruder is and how it operates as well the millions of different complexes of tubes that can be produced which most if not all us use daily for our products.

A plastic tube extruder process is a pretty amazing machine that takes small pieces of Molding Plastic and changes it directly into something very useful. It seems, although simple in theory therefore many people seemingly do not possess the idea to run one? Pellets — fragments of plastic molded into small beads, as is the case with these tiny balls - The melted plastic then squeezes through a machine that has in it die (a hole). The molten plastic is pushed out of the die, and then cools on its way through to create a long tubular object. This process is known as extrusion and it is magic.

Those plastics could be plastic resin, for instance: Polyolefin based including ELE and Metallocene LLDPE, Polyethylene Homopolymer and Co-polymer 10-50% depending on the material use in production PVC (Polyvinylchloride) PP(Polypropylene). Some plastics have unique features that help them excel for certain items. For example, some plastics can be flexed for flexibility – the ability to bend and not break. Others are powerful: Weights. In short, some plastics are heat resistant to the point they can competently serve their purpose in high-heat products. Because of those properties, manufacturers can make a wide array of products.

The very amazing quality of plastic tube extrusion from the point of view that makes these so special is to be formed into just about any size, length and color, also the pvc foam board laminating machine made by Xinhe. By changing the die shape and size, tubes can be manufactured from drinking straw diameter to garden hose. The upside is that companies can make what their products require, and this flexibility is important.

The cost is also an issue — plastic tube making with this method often can be done cheaper than with other methods, PCR said, identical to Xinhe's product wpc board making machine. This is why many businesses turn to plastic tube extrusion when it comes time for them to buy in bulk, as this effectively cuts down the cost of each tube. thus serving as an additional edge when it comes to cost savings which they have earned without compromising on quality output for their clients.

The good knowledge-based systems are smart enough to monitor the machines all day and night in order detect any problems so they can be resolved as quickly as possible, similar to the extruded panel innovated by Xinhe. They see mistakes, they can warn and let the staff correct it right away. This fast response time is necessary to avoid delays in tube production and ensures that everything continues like the proverbial clockwork.

Companies from around the globe are getting green and one of the ways in which this is being done involves taking steps to create far less waste, as well as becoming sustainable, just like the Xinhe's product called pvc profile manufacturing machine. Thus, the plastic tube extrusion can be considered a green process by replacing new pellets with recycled old ones. Plastic recycling is a key way to reduce the waste that ends up in landfills and conserve natural resources.

Pre-Sales: Our sales staff, with over Plastic tube extruder of experience, will recommend the best machine configuration for you. We provide 7*24h service to our clients and provide videos of the factory.In-Sales: Our videos demonstrate the manufacturing process starting from raw steel through to finished products.After-Sales Services: Our engineers offer services on-site at cost and lifelong technical support via video starting from raw materials until the completed product.

We offer customized machines in terms of size, color and even automation. Molds can be customized according to what the final product is expected to look like. As we have grown from Zhangjiagang Xinhe Machinery to Jiangsu Xinhe Plastic tube extruder Equipment Co., Ltd., we have risen to become one of the top 10 Chinese plastic extrusion line producers.

At Jiangsu Xinhe we adhere to the strictest standards regarding the material and thickness of machine steel and provide a detailed list of areas that are at risk Our production lines are built to ensure safety with long lifespan and a low failure rate and a Plastic tube extruder efficient production Our customers have their machines for an average of more than 8 years

Our machines are Plastic tube extruder to meet the needs of the client We offer factory direct sales top-quality products and an extensive after-sales service Our machines are highly valued by our customers from Vietnam as well as Indonesia Additionally they enjoy an extended life span which is longer than eight years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy