Plastic sheet making machines are special plastic sheets that make plastic. For businesses that produce plastic sheets for several purposes, these machines are crucial. Today, we will read its usage into plastic sheet making machines and other factors that are useful to choose it according to your business.

Plastic Sheet Making Machines This type of machine is made for producing sheets from plastic used in numberous products, similar to the Xinhe's product like pvc foam board machine. They use raw plastic material and convert it into finished sheets that can be used in various industries. To begin, the plastic material is heated by machines until it reaches a liquid state and melts. From here they roll or form the melted plastic into a thin sheet to use for various purposes. For creating sheets used in packaging, construction and many other things this process is very important.

For any company trying to be successful in the production of plastic sheets then it must make sure they have chosen the right machine for this and with a good reliable service, the same as plastic pipe extruder machine developed by Xinhe. The machine best for you will depend on your business requirements, the size of your operation and how much money you have to invest. Several considerations you want to think of in order to reach the best decision For instance, what type of plastic are you going to be using? What thickness would you like your sheets to be? At what speed do you want for production? And what level of automation would ease your process? Also, make sure that the device is of good quality and has durability. A name brand that has recognition in the market and is trusted can help you buy a machine that will last through years of use.

Plastic sheet making machines melt and mold plastic through stages to develop top-grade sheets, same with Xinhe's pvc wall panel making machine. Composite sheet manufacturers melt the plastic material while also pushing it through rollers or other methods. These machines contain different essential components to have their proper working. This Canvas has a hopper through which the raw plastic is fed, a heating unit that melts it down to form molten state, an extruder where this mbuttered plastic comes out in desired shape followed by die head shaping it into sheets and later on cooled using cooling units for hardening. The raw plastic pieces are fed to the hopper that are melted fully. Once the plastic is molten, it is passed through a die head to form a thin sheet. Finally, the sheet is cooled down to a specific temperature and cut into appropriate sizes.

The plastic sheet making machines have come a long way, the same as pvc window frame machine supplied by Xinhe. Now, many modern machines are using new and latest technology to manufacture the best quality sheets with good accuracy. As an of this technology, when it comes to the plastic sheet there are some computer-aided design (CAD) software that lets workers develop digital plans for a piece long before any actual manufacturing begins. This is a technology that helps to make sure the end-product has passed all of its specifications and hence, good quality. Moreover, few latest machines also have a distinct set of sensors that keep track with the process while it is going in production. It is particularly used on the conveyors to give workers a hands-free alert so they can resolve any issues and keep production running smoothly.

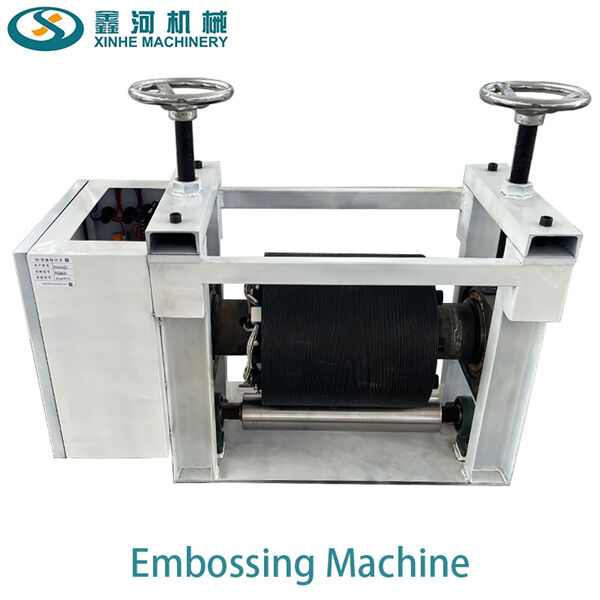

Plastic Sheet Making Machine

Different kinds of Plastic sheet making machines are available which have their specific advantages and disadvantages, along with Xinhe's product pvc profile machine price. For instance, flat die extrusion machines are perfect for thin sheets. This again makes the economically viable, simple to use and low maintenance machines popular among a large number of people. Alternatively, we have the blown film extrusion machine and these are used to create plastic sheets with a heavier form. These types of machineries are great for high-volume production, but you do have to maintain them more than flat die machines and this might be something that some businesses give thought.

We Plastic sheet manufacturing machine the machine configuration to the specific needs of our customers We also provide factory direct sales premium product quality as well as a complete after-sales support Our machines are adored by our customers in Vietnam as well as Indonesia Additionally they enjoy a long lifespan lasting for more than 8 years

We provide custom-made machines that are customized in terms of color, size and even automation. Molds are customizable according to what the final product should look like. As we have grown from Zhangjiagang Plastic sheet manufacturing machine Machinery to Jiangsu Xinhe Intelligent Equipment Co., Ltd., we have become one of the top 10 Chinese plastic extrusion line makers.

Pre-Sales: Our sales staff, with over 5 years of experience, will recommend the appropriate machine configuration for you. We provide 24 hour customer support as well as video factory tours.In-Sales: Our videos demonstrate the manufacturing process starting from Plastic sheet manufacturing machine to the finished products.After-Sales Service: Our engineers provide on-site service for a fee and offer lifelong video technical support starting from raw materials to final products.

We adhere to the strictest standards for Jiangsu Xinhe for machine steel thickness and materials We also offer an inventory of components that are vulnerable The Plastic sheet manufacturing machine we use are built to guarantee safety and have a long life expectancy as well as a low rate of failure and stable efficient production Many of our customers have utilized their machines for more than eight years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy