The process of plastic sheet forming is an inexpensive and efficient method to produce a product, utilized in numerous types of industries. Thermoforming is the process where a flat sheet of heated plastic will be stretched and formed to suit your needs. Although it can be done in an effective manner, one of the best ways is by employing specialized machines for plastic sheet forming only.

Asides these, businesses also are able to save hundreds of dollars from using the machines as they cut off labor costs, identical to Xinhe's product pvc electrical conduit pipe making machine. Comes with ensuring accuracy and also accomplishing the operate in bare minimum staff to help you. So, this is an important part by which companies can produce more at less time and thence bringing them high sales as well like profit taxes etc.

It is a plastic sheet forming machine in which there are sheets that has been molded very precisely. That gives them the capacity to ensure all of those parts operate in perfect harmony, and Shelby too can see it everything as a part-of-see before anything has even been produced. locale See this in matching examples Poweredandeverything matches great results visually. In manufacture, this precision is critical because safety and performance are central to everything that objects perform; in particular the automotive or aerospace industries. Bad tolerance means bad safety. Loose fitting parts may lead to safety issues.

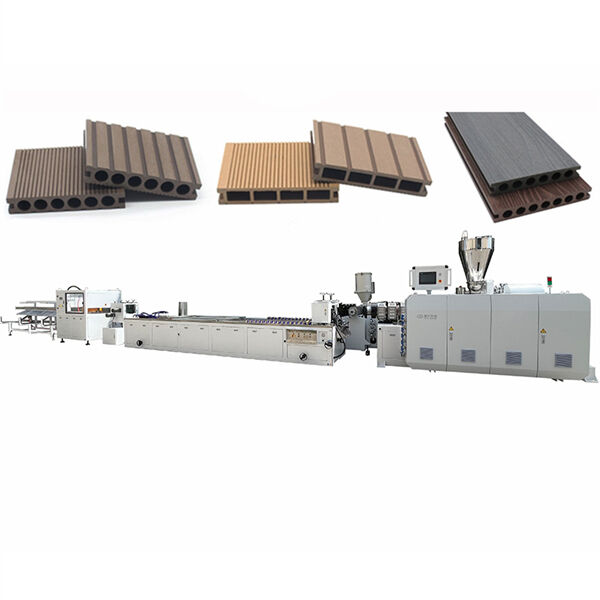

The plastic sheet forming machines, though are relatively new in a world of industrial machinery have completely revolutionized the way products were being made, similar to the plastic sheet extrusion machine price built by Xinhe. So not only can they make more intricate forms, but also faster and with a higher degree of precision than in the past. This means there are niche opportunities for manufacturers to develop something new which could have never been made with their machines.

Now, these beasts are able to allow companies expand their capabilities more than ever before, also the Xinhe's product such as plastic sheet extruder machine. This capability enables them to manufacture parts that are significantly larger and more complex, in a much faster manner than ever before with very high levels of accuracy. The power to produce convenient products faster lets organizations compete in the very fast market and feature shoppers with more valuable, ground-breaking goods.

It comes as we know creating requires time and effort; however, high-performance plastic sheet forming machines help in streamlining a business resulting to ease, same with the pvc roof sheet making machine manufactured by Xinhe. Such machines are designed to carry out this task as quickly and effectively while needing only a small group of workers for performing the job.

This equates to quicker and more affordable production of goods, thereby conserving resources, just like the Xinhe's product called upvc door and window making machine. Streamlining the production process reduces costs for business and thus can help reduce price of product. Since, by their very nature they are able to be more competitive in relation to theirs market segments and thereby help can stimulate business growth.

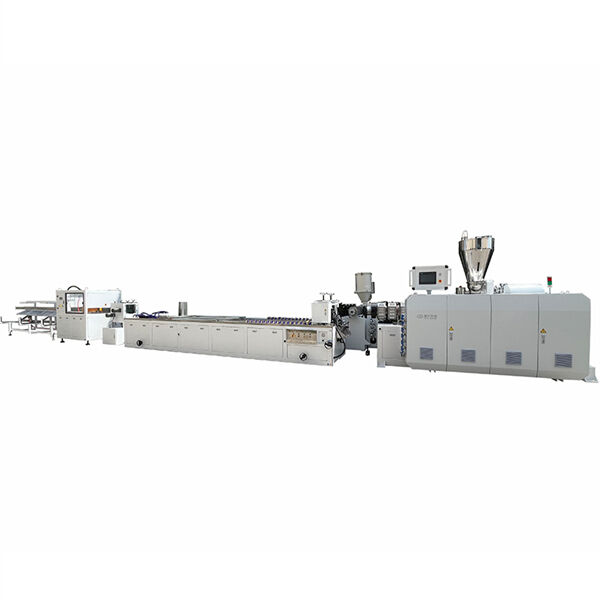

Pre-Sales: Our sales staff, with over Plastic sheet forming machine of experience, will recommend the best machine configuration for you. We provide 7*24h service to our clients and provide videos of the factory.In-Sales: Our videos demonstrate the manufacturing process starting from raw steel through to finished products.After-Sales Services: Our engineers offer services on-site at cost and lifelong technical support via video starting from raw materials until the completed product.

We adhere to strict standards in Jiangsu Xinhe for machine steel Plastic sheet forming machine and the material We also offer a list of vulnerable components We ensure safety by ensuring that our production lines offer long life span and low failure rates and a stable efficient production A majority of our clients have used their machines for more than eight years

With more than 12 years of expertise in plastic extrusion, we offer machines that can be customized by size, color and level of automation. Plastic sheet forming machine can be customized depending on the final product is expected to look like. We've grown from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and have now become one of China's 10 top extrusion lines for plastic.

Our machines are arranged to meet the requirements of the client We provide direct sales from the factory premium products and an extensive after-sales service Our machines have a lifespan that exceeds 8 years They are well-received from customers from Vietnam Indonesia Plastic sheet forming machine South Africa Bolivia and many other countries

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy