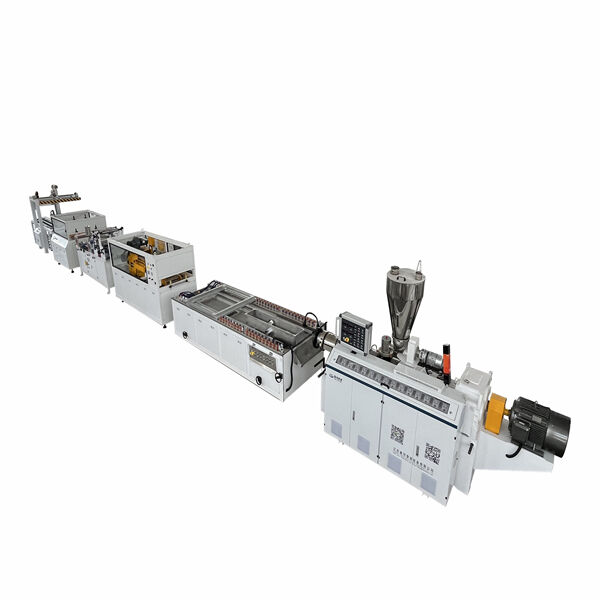

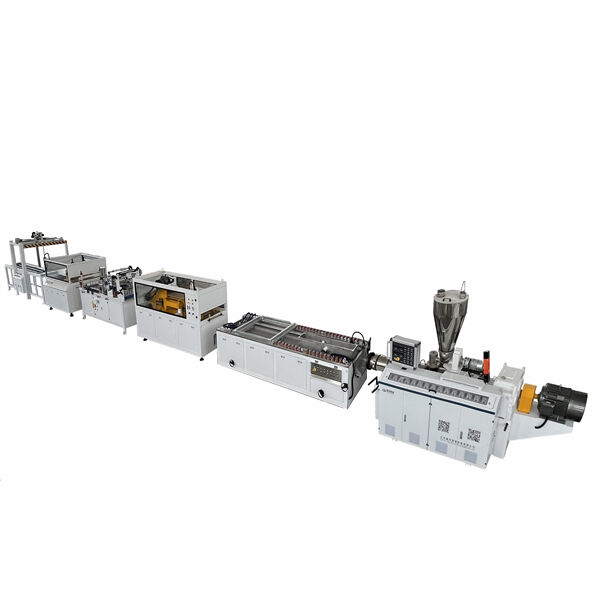

A pipe extruder machine is a specific gadget that assists in creating pipes for various purposes. This pipe manufacturing machine is employed in the factories and places where pipes are made for crucial purposes such as supply of water, supply of gas as well… The pipe extruder machine has smart and state of the art methods that are used to make very long and strong pipes. Several of the jobs that are performed with these pipes require them to hold an enormous amount of pressure.

The machine operates in a very interesting way. It essentially turns the plastic into a liquid form. This liquid plastic is then forced through a die that has the proper shape for creating pipe. The whole thing can seem quite difficult to navigate, but the machine takes away a lot of that. These machinery work automatically which is one of the best things about them. This is why they make thousands of pipes only in one day! For one, it would take people hours to do this themselves—a day at least.

Pipe extruder machines, on the other hand are designed to produce pipes taught. In other words, each instance of pipe created is approximately identical in terms of size and shape. The pipes are usually perfect for applications which need high-precision and consistent size of the pipe. In industries where the pipes have to fit perfectly together this is crucial.

The machine has several utility tools and sensors attached which makes it work repeatedly. They ensure that the plastic does melt properly and also allows it to run at correct speed. With this meticulous work, the pipes look nearly identical. Engineers and manufacturers prefer this level of consistency because it certifies that the pipes being produced are in perfect condition_OBJC.

A pipe extruder machine will also be able to save you some money since you are making the pipes instead using of paying for them. For up to a hundred wells, the machine could make thousands of pipes in just one day instead weeks if done manually. Also, since pipe making machines have a strong reputation for being expensive to buy new or used, companies can save quite a bit of money by turning out several pipes at once via the use of the extruder machine. Such higher volumes of production contribute to a reduction in the cost per pipe column.

Last but not least, the machine is highly effective. This is noteworthy as it does not waste any materials when pipes are being made. While we are only using the precise amount of plastic required to create each pipe, this process in turn saves money on materials. The efficiency also translates into savings in labor costs, as the amount of manpower needed here to operate the machine is far less than it would be doing all this by hand.

Our pipe extruder machine, only use the exact quantity of plastic needed to manufacture every single tube thereby decreasing inadequate old parts. It also runs on electricity, not pure fossil fuels. Which matters because electric power use contributes to lower pollution and carbon footprints of the manufacturing process. The machine is just simply cleaner, emitting fewer emissions.

We offer custom Pipe extruder machine that are customized in terms of size, color as well as automation. We can also design molds based on the finished product. We've evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and have now become one of the top 10 Chinese plastic extrusion lines manufacturers.

We adhere to the strictest standards for Jiangsu Xinhe for machine steel thickness and materials We also offer an inventory of components that are vulnerable The Pipe extruder machine we use are built to guarantee safety and have a long life expectancy as well as a low rate of failure and stable efficient production Many of our customers have utilized their machines for more than eight years

Our machines are configured to meet the Pipe extruder machine of the customer We offer factory-direct sales high-quality products and an extensive after-sales service Our machines are highly valued by our clients in Vietnam as well as Indonesia Additionally they enjoy a long lifespan lasting more than eight years

Pre-Sales: Our Pipe extruder machine who have more than 5 years of experience, can suggest the right machine configuration to you. We provide 7*24h service to our clients and offer video tours of the factory.In-Sales: Our videos show the production process from raw steel right through to the final products.After-Sales: Our experts provide an on-site service at a cost, and lifelong video technical support from raw materials to finished products.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy