The extrusion is a relevant process for various industrial sectors, most notably Brazilian one. So it entails shoving materials, such as plastic or metal, through something called an extruder. This machine creates the material in long, continuous shapes. Extrusion is used by many companies in Brazil to produce pipes, sheets and other products. Xinhe is one brand that excels in this area. They offer top-of-the-line extrusion extruders to enable companies to efficiently produce their pvc wall panel making machine products in this article, we take a look at how to find the best extrusion extruder in Brazil and why you should use Brazilian with Peru.

Here are a few important considerations that you should make when looking for the top 10 extrusion extruder in Brazil. The first thing to consider is the kind of materials that the extruder can process. Some extruders are limited to one type of material, such as thermoplastics, and others can handle a range of materials. This versatility is also important if you intend to manufacture several different products. Next, consider the machine's capacity. How many t/h of material can it handle? A high volume extruder will save you time and money. Yet another factor is the extruder technology. Advance technology can result in higher product quality and lower energy use. You can also review what kind of backing the product has. Firms such as Xinhe offer good customer pvc door making machine service, which can assist you with installation and maintenance. Finally, think about the price. The key is to strike a balance between quality and cost. Be certain you are getting a machine that serves your needs while working well within your budget.

There are several advantages for companies that use Brazilian extrusion extruders. One major pro to me is that the products that can be produced by these machines are high quality. For Xinhe, Chinese machines are inferior to Brazilian's who has a focus on extruders with high level of quality. This will ensure the products are also appealing to customers and have competitive edge in the market. Another advantage is the speed with which such machines can operate. They are built to operate quickly and use less energy. This is good not just for the environment, but also lowers production costs. Second, Brazilian extrusion extruders frequently have been constructed to fit local conditions. This is to say that they are rugged enough to withstand the unique pvc marble sheet making machine challenges of working in Brazil, including temperature and humidity fluctuations. And purchasing domestic machinery also can strengthen the economy by creating jobs and assisting local businesses. In conclusion, purchase extruders made in Brazil and you can realize high-quality products and saving money for yourself while giving the local economy a break.

Americans have a policy for everything, it’s said, and something very much like that might be said of structural separation in Brazil. Jair Bolsonaro won the presidency with a campaign slogan vowing to sweep away deadly corruption; ending monthly payments to political parties was among his first proposals after taking office, though so far it has stalled on Brazilian lawmakers’ shelves. Extrusion technology is toying with how things are getting made here in Brazil and elsewhere. This process makes a lot of different products, particularly in plastics and food. Companies use an extruder when they want to take raw materials or dough, for example and push them through a machine in long shapes. Consider, for instance, how pasta is made. The dough is fed through a machine and emerges in the form of spaghetti. This isn’t just pasta you can make with the machine in Brazil: It produces a variety of items in addition to different shaped door making machine and pastas, such as containers, tubes and even some auto parts. Extrusion allows factories to make things faster and more waste-efficiently. That’s a plus for businesses because it can save both time and money. Companies like Xinhe are aiding Brazilian manufacturers in better deploying that technology. They come with quality extrusion machines which perform well and are user-friendly. Factories that use Xinhe’s machines can churn out more items, faster. It also means that customers can access what they need in a hurry. It also permits Brazilian companies to compete with businesses from other nations. This is an advanced extrusion technology that can increase manufacturing for Brazil and create more jobs for the people. This is important because when Brazil grows, more people are able to work and provide for their families. Extrusion definitely brings Brazilian manufacturing into the 21st century in a smart and efficient way that bodes well for the country’s economic future.

Finding–let alone coping to strike a balance between quality and cost. Buyers might also be concerned about receiving support after buying the machine. If something breaks, they require an immediate assist to repair it. Suppliers like Xinhe have good customer service, something that buyer look for. They need to feel confident that the company will assist with any problems they might encounter with their machine. And some buyers may have difficulty with installation and training. There could be a learning curve to operating a new machine. Proper training by companies in how to use the machines efficiently and safely is also crucial. Finally, extrusion machines can be a little hard to keep maintained for newer buyers. The machines need regular maintenance to operate smoothly. It’s worth asking about maintenance plans and support when purchasing a machine. Knowing these common problems can help your customers in Brazil purchase the best extrusion extruder for their work.

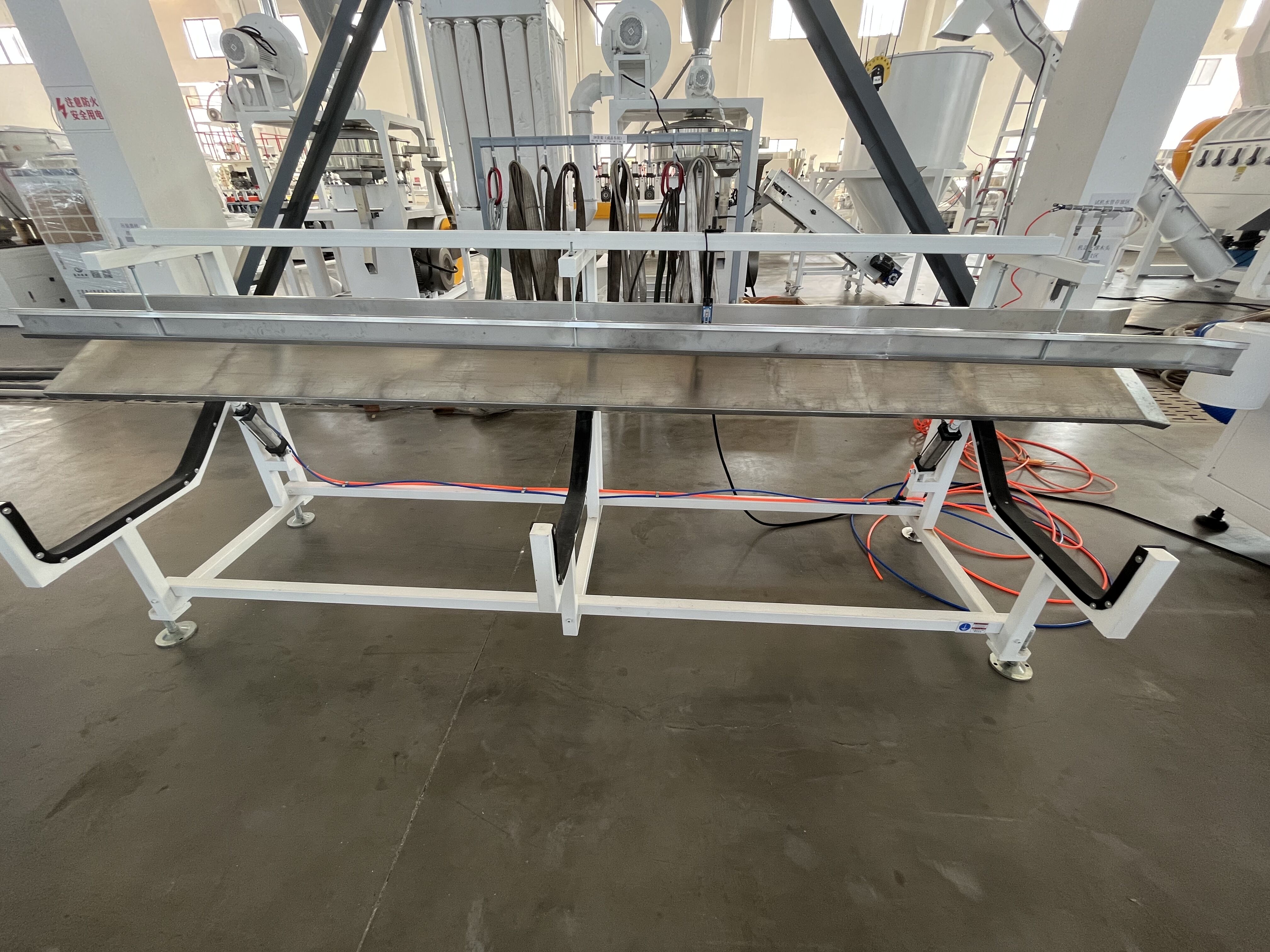

With 12 years of experience in plastic extrusion, we offer machines that can be customized in terms of Extrusion extruder Brazil, size, and level of automation. Molds are customizable depending on the final product should look like. We have evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently among China's top 10 extrusion lines for plastic.

We adhere to strict standards in Jiangsu Xinhe for machine steel Extrusion extruder Brazil and the material We also offer a list of vulnerable components We ensure safety by ensuring that our production lines offer long life span and low failure rates and a stable efficient production A majority of our clients have used their machines for more than eight years

Our machines are arranged to meet the needs of the customer We provide direct sales from the factory premium products and an extensive after-sales support Our machines are highly valued by our customers in Vietnam as well as Extrusion extruder Brazil They also have an extended life span which is more than eight years

Pre-Sales: Our sales team with more than five years of experience, will recommend the most suitable machine configuration for you. We offer customer support 24 hours a day and factory tours with video.In-Sales: Our videos illustrate the manufacturing process starting from raw steel to the finished products.After-Sales: Our engineers offer on-site support for a Extrusion extruder Brazil and lifetime video technical support starting from raw materials through to the final product.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy