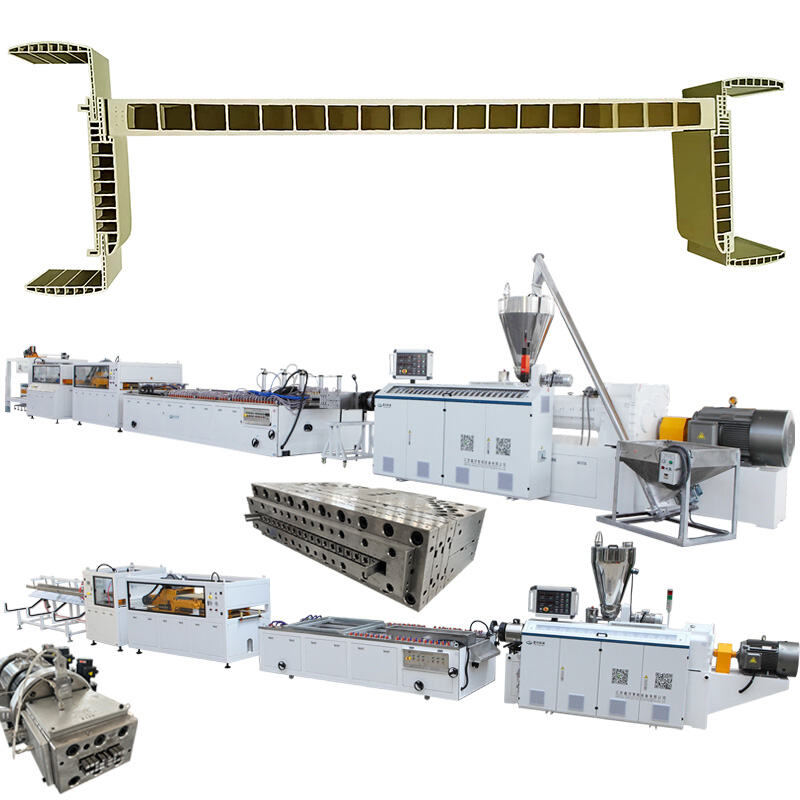

Design of Temperature Control System in WPC Door Panel Production Line

2026

In the WPC door panel extrusion molding process, temperature control is a key factor in ensuring product quality. The temperature control system precisely adjusts the temperature of each heating zone of the extruder and the hot die, and controls the temperature of the cold die through cooling water, achieving uniform melting and stable extrusion of the plastic raw material.

1. System Composition

The precise temperature control system mainly consists of three parts: temperature sensors, controllers, and actuators. The temperature sensors monitor the actual temperature of each heating zone in real time. The controller calculates the control quantity based on the deviation between the set value and the actual value using a PID algorithm, driving the actuators to adjust the heating power. The cooling water circulation system mainly consists of a chiller and a cooling tower, realizing the circulation of water.

2. Control Strategy

The PID control algorithm is adopted, adjusting the proportional, integral, and derivative components to ensure that the system temperature quickly and stably reaches the set value. For plastic extrusion processes, temperature control accuracy is typically required to be within ±1°C to ensure the uniformity of sheet thickness and surface quality. Simultaneously, a suitable chiller is matched to ensure the cooling water temperature is around 20°C, guaranteeing the vacuuming effect and the molding of WPC door panels.

3. System Features

The modern temperature control system has the following features:

- Multi-zone independent control to meet the temperature requirements of different plastic materials

- Digital display and automatic recording function

- Over-temperature alarm and automatic protection mechanism

- Linked control with other extruder systems

The cooling capacity of the chiller needs to be configured according to the number of door panel and door frame production lines, 20HP-50HP, mainly air-cooled and screw-type, offering great flexibility.

4. Application Effects

Precise temperature control can significantly improve the production efficiency and quality stability of plastic sheets, reduce scrap rate, and lower production costs, making it one of the core technologies of WPC door panel extrusion molding equipment.

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ