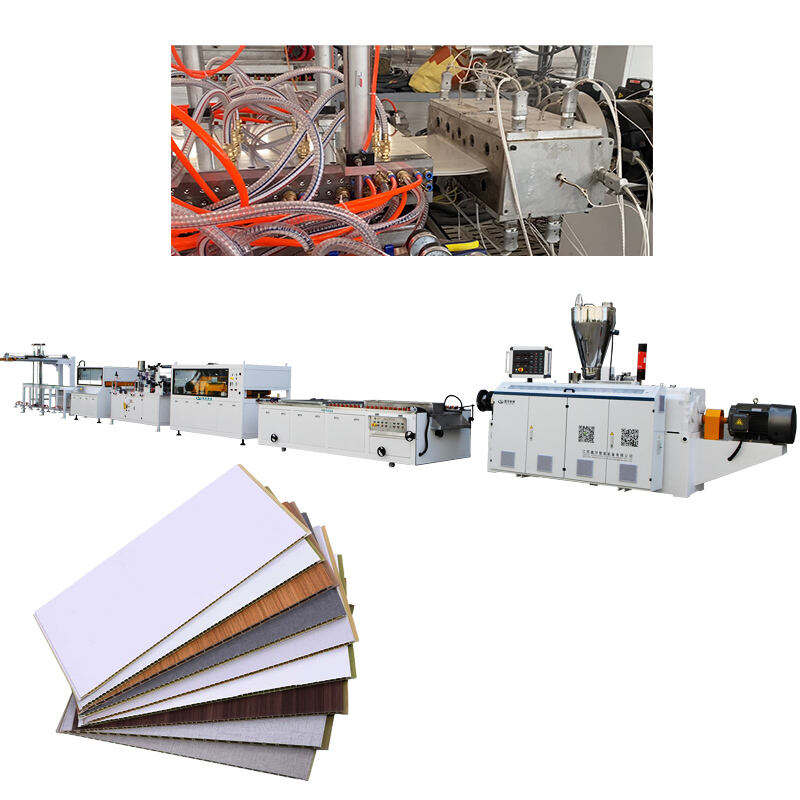

With the constantly increasing costs of the raw materials, the tendency towards more efficient and cost-saving approach to the problem of the grating manufacturing sector is becoming more and more obvious. Being one of the leading manufacturers of advanced manufacturing machines, Xinhe has taken a major role in this shift with their WPC micro-foam grating manufacturing machines winning the challenges presented by the increased costs of the material combined with the great value of the output as compared to conventional PVC grating machines.

Micro-foam grating is of better quality than PVC grating

The manufacturing machines of WPC micro-foam grating made by Xinhe ensure enhanced structural integrity of grating. This high quality is based on high production processes incorporated in the machines used by Xinhe to make the end product be stronger in longevity and resistance to the environment compared to the PVC grating in the ability to last.

Micro-foam grating is not easily damaged during transportation

It has superior impact resistance owing to the peculiarities of WPC micro-foam grating manufactured with the help of machines provided by Xinhe. It is a feature that greatly eliminates the danger of harm on delivery and lowers loss and helps the product to be delivered to the customers in its best form which is one of the advantages over PVC grating.

Micro-foam grating is easy to install

The WPC micro-foam grating manufacturing machines developed by Xinhe are built to manufacture grating that makes the installation process easy. Being lightweight and sturdy, which is achieved through highly specialized methods of Xinhe, enables faster and easier installation, saving time and replacement costs relative to PVC grating.

Long-term cost efficiency amid higher raw material costs

There is an increasing cost in raw materials which has been met by good long term cost expectations between Xinhe WPC micro-foam grating manufacturing machines and the cost of raw materials. Durability and quality of the resulting grating is high which lessens demand in-line replacement and maintenance costs balancing the material cost of production outweighing the cost useful advantage of other re-grating machines made with PVC.

To sum up, the WPC micro-foam grating production machines offered by Xinhe are the most suitable to use when the cost of raw materials starts rising. Their capacity to manufacture superior quality grating made of transport resistant and easy to install with long term cost effectiveness one that will make them the next generation equipment to manufacture grating by gradually phasing out the PVC grating machines.

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ