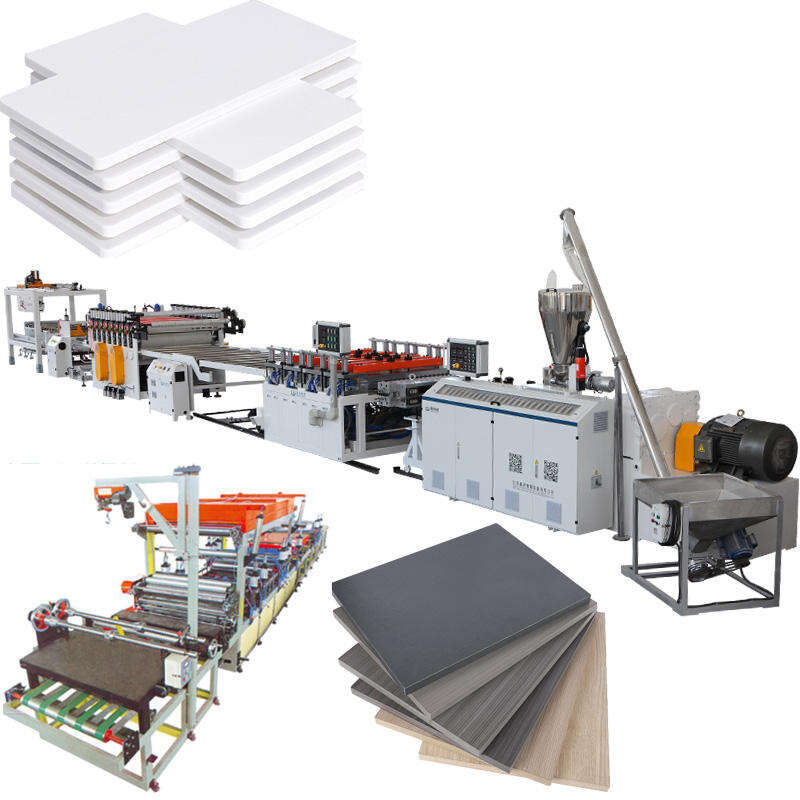

Foam board manufacture is an interesting process that brings forth all manner of useful products such as advertising boards and cabinet boards. So, the thing we are going to do today is, we are going to see if we can establish a production line of being able to make these boards at different sizes, from say 3mm, all the way up to 20mm thick, with a really nice veneer wood finish.

Strong-smell foam board process of advertising and cabinet board (1) Normal foam board (2) Foam boards and raw materials for stands(profiles of various shapes, such as angles, channels and so on.) (1) Machine foam extrusion machine (2) It consist of extrusion, die, cooling system,, drawing, cutting and discharging devices.

Now, before we get into how to set up our production line, let’s go over what producing foam board is in the first place. Foam boards are manufactured by injecting foam material with other substances in order to form a durable and light board. Such boards are often used for advertising and cabinet making due to their strength and versatility.

Q: How to prepare for a 1220mm foam board production line?

We’re going to have to get some equipment and machinery in place to make our foam panel. The secret to running an efficient line is using the right tools for the job. We will also need machines to cut, shape, and weld the foam material to form the boards. To do your best: Make sure all your gear works properly.

Precision and repeatability in the production runs of boards to 3-20mm thick with veneer cover finish

Accuracy and uniformity in the thickness of the sheets is one of the most crucial factor of foamboard manufacturing. For advertising & cabinet Board :we need 3mm-20mm thickness board depending on the use. What's more, timber veneer finish makes the boards look beautiful and natural. With attentive manufacture and sourcing you can get a PERFECT board each and every time.

Adopting cost effective methods of production to achieve the desired level of output and good level of waste control

A successful production line is built on speed. Efficient Production If we use our resources effectively, we can get more out with less waste. This might mean simplifying our process, setting up our workflow for efficiency, and investing in energy efficient tools. Efficient focus will allow us to make the most product possible in the least amount of time which then ultimately means savings and profit.

Guaranteeing quality control for lasting and durable boards

And last but not least, quality control needs to be in place to develop boards that are robust and high performance. Quality control is the inspection of the boards as they are made during the whole manufacturing process to make sure they meet our standards. This might be verifying the thickness, finish and general quality of the boards. Through strict quality control measures, we know we are delivering a superior board that will execute on performance for our customers.

In conclusion, producing advertising and cabinet board with wooden veneer finish based upon 1220mm wide foam board production line has a promising and rewarding future. If we have a good understanding of foam board production, the proper equipment is installed, good thickness and finish are controlled, manufacturing settings are scientific and reasonable, scientific and standardized quality control procedures are implemented, then, we can make the high-quality boards suitable for diverse usages. Thanks to Xinhe's professionalism and pursuit for excellence, we have one of the strongest team producing high-quality Products which are now being sold to all over of the world.

Table of Contents

- Q: How to prepare for a 1220mm foam board production line?

- Precision and repeatability in the production runs of boards to 3-20mm thick with veneer cover finish

- Adopting cost effective methods of production to achieve the desired level of output and good level of waste control

- Guaranteeing quality control for lasting and durable boards

EN

EN

AR

AR

BG

BG

HR

HR

NL

NL

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SL

SL

UK

UK

VI

VI

HU

HU

MT

MT

TH

TH

TR

TR

AF

AF

MK

MK

HY

HY

AZ

AZ

UR

UR

BN

BN

LA

LA

NE

NE

MY

MY

KK

KK

UZ

UZ