If you have never heard of a twin-screw extruder. It may appear to be a giant, complex machine but once you understand the basics it's really not that difficult. A twin-screw extruder is a unique device with two lengthy screws to combine chemicals and heat them together. This is what makes the then unknown and unseen, that new fun thing to create. It's like baking a tasty cake. All the materials would be blended using a twin screw extruder, instead of your normal mixer.

One of the neatest features of twin-screw extruders is that they can mix materials that are inherently incompatible, such as oil and water. This opens up new possibilities for manufacturers to compete by making things that we could not manufacture before. Also, they can make elastic stuff like cling film which is a whole new dimension. This is creating limits for our imagination with these machines.

As with almost any technology, there are some significant upsides to using twin-screw extruders in the manufacturing process. The main advantage is that they are highly efficient. This ensures that no material is wasted during the process and also does not create a big fuss while mixing. Other good point is they stir everything in together well too which helps to make it all better. Well-made products equals happiness for all parties involved!

Versatility of Twin Screw Extruders Another reason that twin screw extruders get their own heading. It can be implemented to form various compliance products, delicious foods and valuable medically approved instruments. So manufacturers can run multiple products on a single machine, saving them equipment costs and factory floor space. A multi-tool that can do everything!

The twin-screw extrusion is revolutionizing numerous industries that we have in today. Twin-screw extruders have applications from the simplest of snacks (like potato chips and breakfast cereals) to the most advanced niche foods, like protein-based snack foods. They are also employed for producing healthier product, such as protein bar or gluten-free bread. In other words, people will be able to eat all of the food that they love and at the same time consumers can also choose healthier options.

The plastics market include usage of twin screw extruders for developing day to day functional products like water bottles and plastic bags. They are also working on new, more environmental plastics that is sustainable and environmentally friendly such as biodegradable plastic is a type of environment —friendly types which can be broken down by bacteria or deconstructed chemically to simpler molecules. This is significant because it has helped decrease waste as well as save our environment.

An extra exciting feature of twin screw extruders is that itis very eco-friendly. Since they are really effective, there is a less energy used vs. other devices and likewise lower ergonomic waste products output (as result of the job done). All of this means we can build incredible products and at the same time help to save our planet. Isn’t that wonderful?

Pre-Sales: Our sales staff with more than five years of experience, will Twin-screw extruder the best machine configuration for you. We provide 24 hour service to our clients and offer video tours of the factory.In-Sales: We can provide videos of production, from raw steel to the finished product as well as videos of production on the total line.After-Sales Service: Our engineers offer on-site support for cost and lifelong technical support via video from raw materials to the finished product.

Our machines are arranged to meet the needs of the customer We provide direct sales from the factory premium products and an extensive after-sales support Our machines are highly valued by our customers in Vietnam as well as Twin-screw extruder They also have an extended life span which is more than eight years

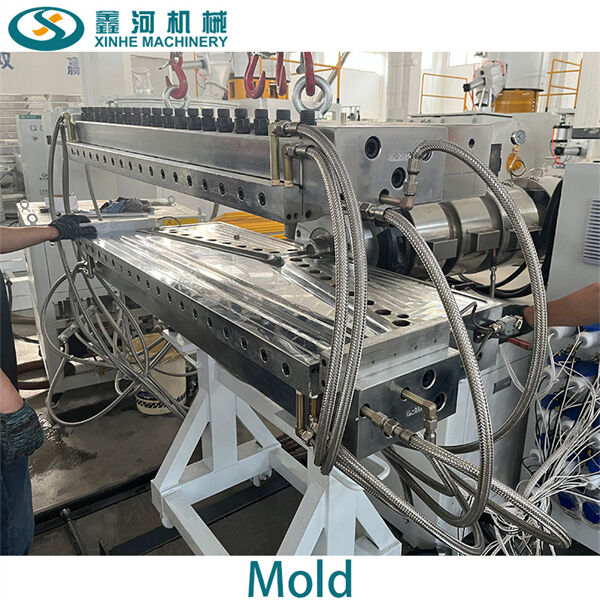

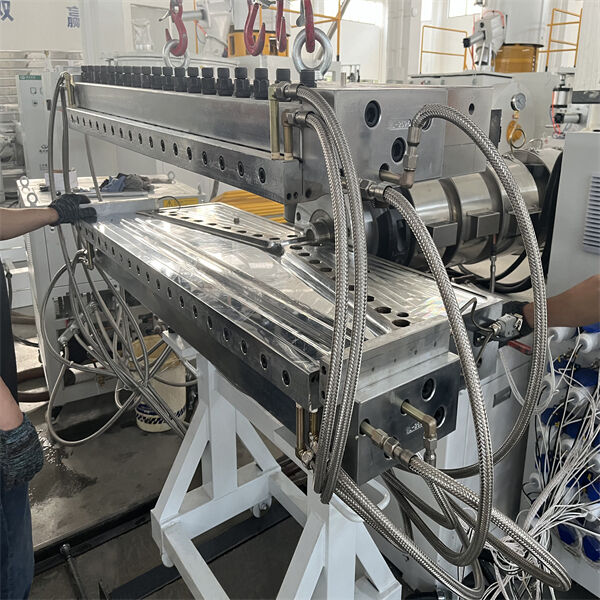

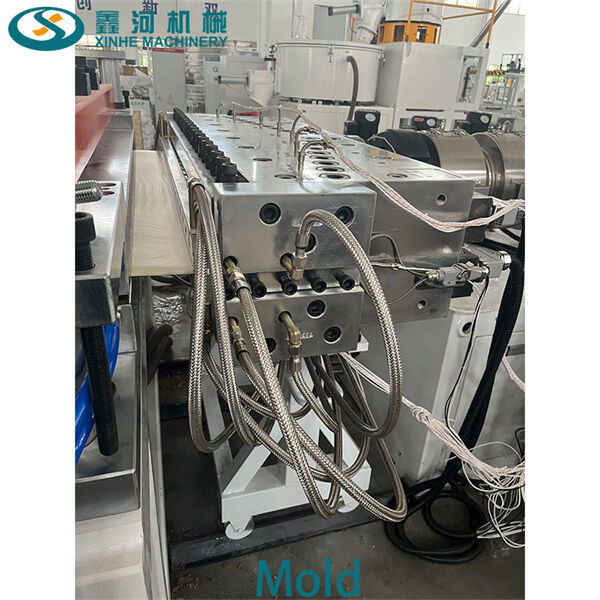

We provide custom-made machines that are customized in terms of color, size and even automation. Molds are customizable according to what the final product should look like. As we have grown from Zhangjiagang Twin-screw extruder Machinery to Jiangsu Xinhe Intelligent Equipment Co., Ltd., we have become one of the top 10 Chinese plastic extrusion line makers.

We Twin-screw extruder strict guidelines for Jiangsu Xinhe for machine steel thickness and material We also offer a list of the most vulnerable components Our production lines are built to guarantee safety and have long-lasting life expectancy and a low failure rate and a steady reliable production A majority of our clients have utilized their machines for more then 8 years

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy