An excellent reason for the shape from twin screw extrusion technology is that it can be employed as a simple, quick and adaptable tool to produce countless items. Using this tech, they can essentially produce a wide range of things — from pasta to pet food all the way up to certain types of plastics that decompose naturally. It is also versatile as the twin screw machine can process a range of materials, from grinding powders to chewing gum (a mix of liquid with sticky bits)

Twin screw extrusion technology is cost as well as time effective to manufacturers. This method is very Flexible any way there some action can be done at a time like tack features, forma the product to get cut Historical Definition. That efficiency carries through to the end process too, with products able to be finished more quickly than conventional methods.

This is a very favorite machine with manufacturers, due to several reasons. This technology has the greatest benefit that it helps in standardization and producing quality products. Creates the impression of a trustworthy product increases likelihood that next offer on your list will sell Shoppers love to be able to see what they are buying, and if the method leads them to happiness or pleasure this time around shoppers might just load up another (happiness) cart for later.

A key advantage of twin screw extrusion technology is the capability to modify immediately, without any additional steps, like texture appearance and size shape etc. It would help to made the products more compatible with the diverse use cases and preferences of consumers. In addition to this technology can also save moisture in food products and thus consume a reduced shelf life and harm the environment.

None other than twin screw extrusion technology is considered as the best model for this process, where not only harms the item efficiency but also range to up. Manufacturers are able to produce their products in high volumes with a twin screw machine. This would also help in automating a number of operational tasks ultimately speeding up production lines. Automation to be able to robots that makes people directing machines and the less physical, as errors while creating things.

A further advantage of twin screw extrusion technology is that there are fewer waste materials created during the manufacturing process. All this has meant that less of the stuff is wasted, which means a cost savings for manufacturers. As such, it is more economical (for the firms) than trash disposal and we can consider that also a gain-to-waste approach considering project management.

It also applies to foods made on twin screw machines, and products intended for a particular social class of the population having as special dietary needs or suffering from food allergy. Such as manufacturing suppliers that continued pelletizing gluten-free pasta and snack seed items into veggie meat alternatives. It is also demonstrated with the versatility and consumer orientation of twin screw extrusion technology.

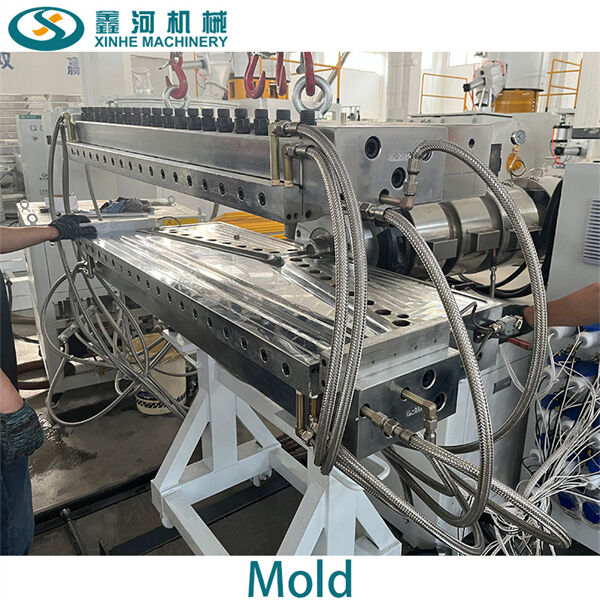

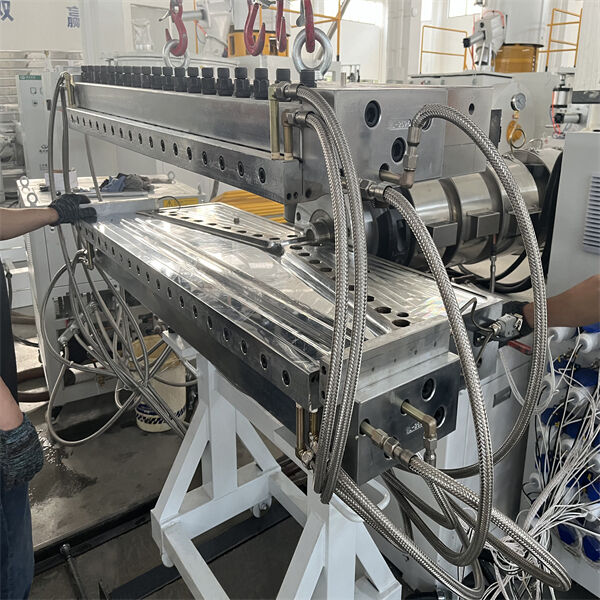

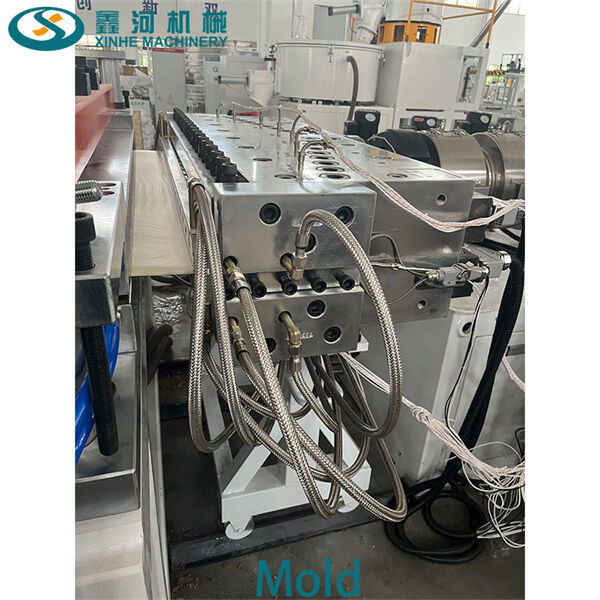

We offer customized machines in terms of size, color and automation. Molds are customizable in accordance with what the final product is expected to look like. We've evolved from Twin screw extruder and have become one of the top 10 Chinese extrusion lines made of plastic.

At Twin screw extruder we adhere to the strictest standards regarding the material and thickness of machine steel We also provide a detailed list of dangerous parts Ensuring safety measures our manufacturing lines provide high durability with low failure rates and stable reliable production Our customers rely on their machines for an average of more than 8 years

Our machines are configured to meet the needs of the client We provide factory direct sales Twin screw extruder products and an extensive after-sales support Our machines last of over 8 years and are well-received by customers in Vietnam Indonesia Saudi Arabia South Africa Bolivia and many other countries

Pre-Sales: Our sales team with more than five years of experience, will recommend the most suitable machine configuration for you. We offer customer support 24 hours a day and factory tours with video.In-Sales: Our videos illustrate the manufacturing process starting from raw steel to the finished products.After-Sales: Our engineers offer on-site support for a Twin screw extruder and lifetime video technical support starting from raw materials through to the final product.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy