Have you ever stopped to consider how PVC wall plastic profile extruder panels are actually made? These need to be prepared through a PVC wall panel production line. Today, this incredible piece of engineering will be explained and we break down into how it works today followed by the process for making them (the panels) + why these are useful for businesses. XINHE will also discuss some of the typical problems that may occur during production and provide them an effective solution. What is a PVC wall panel production line? A structural device for the continuous extrusion line of building materials used to manufacture high-quality plastic-PVC This type of board is suitable not only for making walls, but also other products like doors, windows and so on. There are many different parts of this machine, and each piece has a unique responsibility in the process of manufacturing panels. Its principal sections are the extruder, mixer dwelling machine and cutting tool.

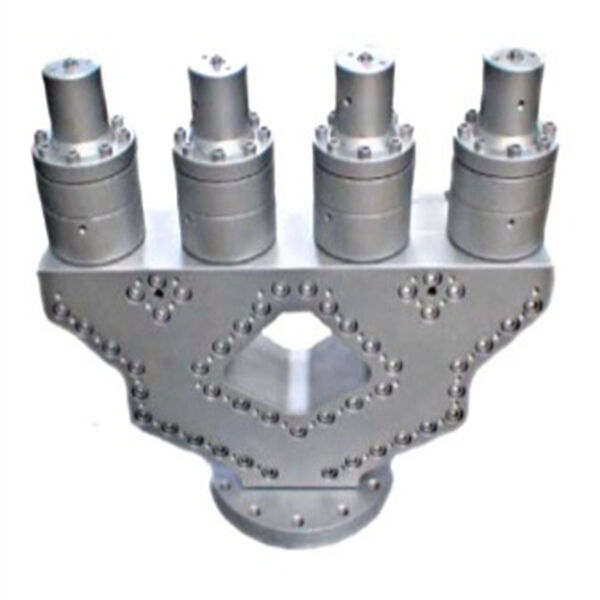

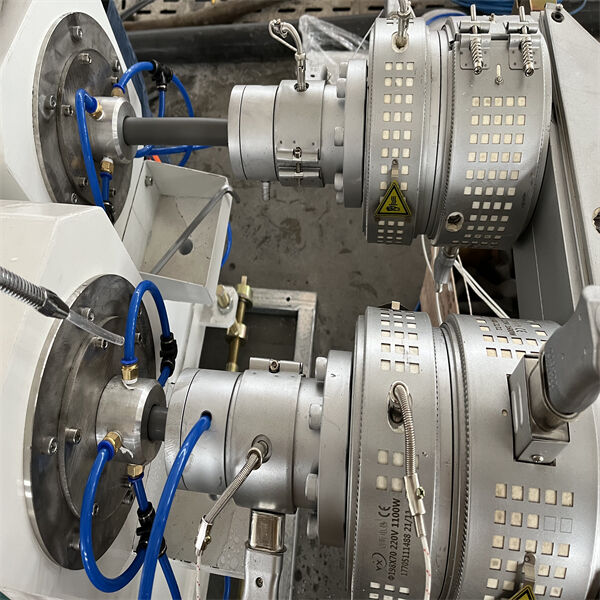

Starting with the Extruder It is the part where raw PVC plastic extruder material melt down and amalgamated perfectly for making a smooth mixture. Once its materials are melted and mixed, it is then forced through a custom shape sitting ate over the part called a die to make the appearance of a blank. This is important because it becomes the base of making all the panels. Further down the line, we have a mixer. The mixer is the key point to determine that each PVC mixture type has correct properties It mixes in other things like colour (to make the panels look pretty) and stabilizing agents to keep them strong. This is important to check that all the material inside are evenly mixed and satisfactory.

After the mixer is the calibration table. It is responsible for ensuring that the PVC extruder plastic panels are of the right length when made and cut. Cooling and heating are utilised via the calibration table in order to ensure that panels have been fully formed and at a specified thickness. This process ensures when the panels are used to build that they would go in smoothly.

The table of calibration, developed in the laminating machine. It is the device for the final appearance of PVC panel. It pastes a layer of decorative film on the PVC plastic sheet extruder panel. It is the film that provides a final touch to the panel and thereby makes it usable in buildings or where ever decoration matters. A good laminate protects the panel from damage in addition to looking pretty.

The table of calibration, developed in the laminating machine. It is the device for the final appearance of PVC panel. It pastes a layer of decorative film on the PVC plastic sheet extruder panel. It is the film that provides a final touch to the panel and thereby makes it usable in buildings or where ever decoration matters. A good laminate protects the panel from damage in addition to looking pretty.

At Jiangsu Xinhe we adhere to the strictest standards regarding the material and thickness of machine steel and provide a detailed list of areas that are at risk Our production lines are built to ensure safety with long lifespan and a low failure rate and a Pvc wall panel production line efficient production Our customers have their machines for an average of more than 8 years

With over 12 years of experience in Pvc wall panel production line, we offer machines that can be customized in terms of color, size, and even automation levels. We can also customize molds based on the finished product. We've evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently one of China's top 10 extrusion lines made of plastic.

Our machines are Pvc wall panel production line to meet the needs of the client We offer factory direct sales top-quality products and an extensive after-sales service Our machines are highly valued by our customers from Vietnam as well as Indonesia Additionally they enjoy an extended life span which is longer than eight years

Pre-Sales: Our sales team with more than five years of experience, will recommend the most suitable machine configuration for you. We offer customer support 24 hours a day and factory tours with video.In-Sales: Our videos illustrate the manufacturing process starting from raw steel to the finished products.After-Sales: Our engineers offer on-site support for a Pvc wall panel production line and lifetime video technical support starting from raw materials through to the final product.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy