We are surrounded by plastic. Plastic is the material using for making many things, like toys, bottles, bags or packages. Many people are using plastics today, even though you may be oblivious to it. A machine called an Extruder is used to make these plastic products. It is basically a step up from your basic hot glue gun that melts plastic parts together making different objects. Machines of this type are critical to plastic manufacturing as they allow multiple items to be made at once, quickly and efficiently.

Nevertheless, there are new and improved extruders coming out. These are more than the tirescr The higher speed of operation means they can actually produce really good plastic components in a much shorter time as well. Also, there a few available in light of the way they are out quickly and endeavor this makes plastics handling plants to race. So, it means that the more products a plastic factory can produce in less time by increasing their productivity and earn extra money. This allows them to produce the things that people need and want much more quickly!

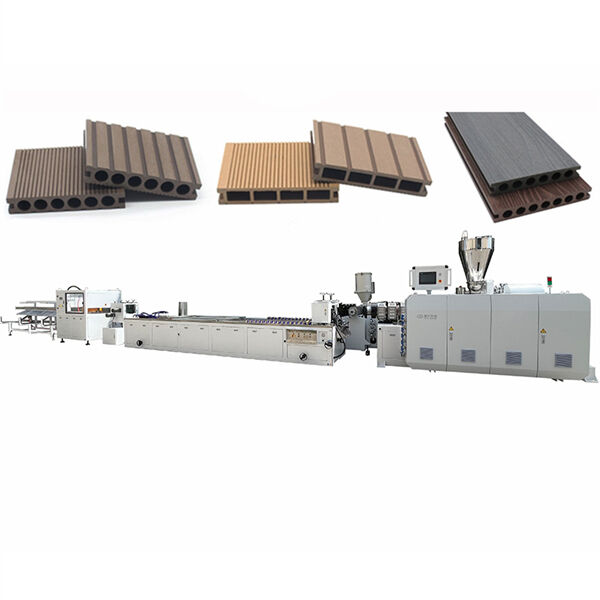

Think of all the money that a business can save, by using such an invaluable tool like plastic extruder machines. These can be made in different sizes and shapes to prepare any plastic type of products Machines are availableThe type of machines that you require will depend on the packaging material and machinery used before for packing various items.These machine come in different sizes -Perfect small ones, helping users to pack toys or other merchandiseMedium-sized one'sIt makes it easy to create large package materials.Large /jumbo sizedAnd these machines which do not have a specific sizeThese units don't as well need any kind of maintenance so they work wonders be if order placed by business big or small. Businesses, even small ones can benefit from the pricing divergence of these machines and large productions might collocate multiple units to meet the high demand.

One good thing — extruder is not of same type for all businesses, thus there are special machinery that you can personalize or we should use the word Modify it as per our business requirements. These machines can be set by the maker to make whatever product they want. Say a company wants to produce manufacturing machine for new type of toy, they can easily get the designing mode. This will be beneficial for the business as by using specialized software you can tailor these machines to your company exactly how they want it making its more likely that create Poor Man's Megazord.

Plastic extruder machines are manufactured to generate a considerable measure of plastics merchandise concurrently. This is the reason for these machines are called special purpose automatic machine which can generate high volume of output on very less time. This is also very useful for the factories so that they can provide a better need of product what customer needs. The more items produced in a shorter time, the higher their reward. Bigger plastic bottles mean substantial equipment is used at the manufacturing plant, so if a company wants large ones then those machines have to crank out more for revenue.

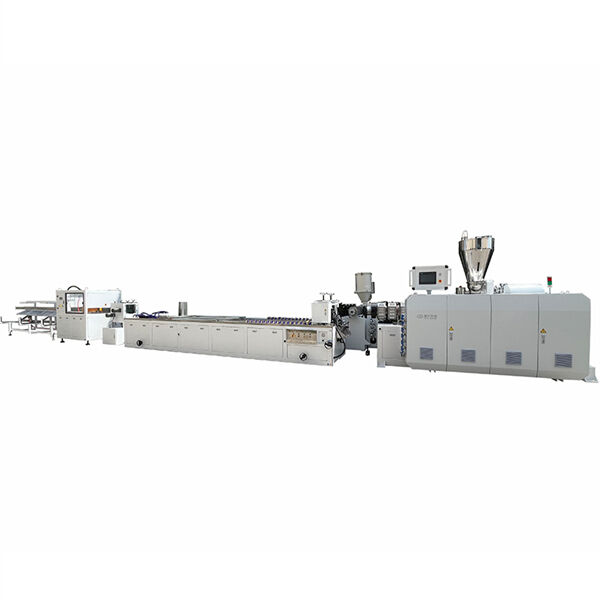

We adhere to Plastics extruder machine for Jiangsu Xinhe for machine steel thickness and material We also offer a list of vulnerable components The production lines we use are designed to be safe with an extended life-span low failure rate and a stable efficient production A majority of our clients have been using their machines for more then 8 years

Our machines are arranged to meet the needs of the customer We provide direct sales from the factory premium products and an extensive after-sales support Our machines are highly valued by our customers in Vietnam as well as Plastics extruder machine They also have an extended life span which is more than eight years

Pre-Sales: Our sales staff, with over Plastics extruder machine of experience, will recommend the best machine configuration for you. We provide 7*24h service to our clients and provide videos of the factory.In-Sales: Our videos demonstrate the manufacturing process starting from raw steel through to finished products.After-Sales Services: Our engineers offer services on-site at cost and lifelong technical support via video starting from raw materials until the completed product.

We offer customized machines in terms of size, color and automation. Molds are customizable in accordance with what the final product is expected to look like. We've evolved from Plastics extruder machine and have become one of the top 10 Chinese extrusion lines made of plastic.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy