It is used as an extruder which works by making many different sorts of things. The process involves taking materials (plastic, metal or food) and heating them until it is soft enough to be shaped according to the desired shape. The extruder forces the softened materials through a component called Die. This tells the die how it should shape the materials Soft materials entering the die adjusts to that shape. It sounds complicated but that entire process of shaping materials is what's known as extrusion.

An extruder has the capacity to produce articles of different substances. You can use things like plastic, metal or even some food items. It warms these materials in the extruder till they are flexible sufficient to mould. Once the materials are in a molten state, they pass through a die that makes converting them into an exact shape possible. One intriguing item to say the least is that there are different sizes of extruders. There are the small ones for little tasks and there are large models that do big jobs in factories. Extruders are vital across various industries, making everything from toys to packaging possible.

Extruder: The primary responsibility of an extruder is to convert materials into fresh and durable material. It is invaluable because it enables factories to produce products quickly, and removes defects faster. Rather than employees forming goods by hand, an extruder can manufacture several copies with the same form within four minutes. It has the capability of mass producing and this saves a lot of time along with money, ultimately making it production process much more effective. Extruders also assist in keeping every single item prepared uniform and with the exact same quality, a requirement for many companies.

There are a lot of different types and picking exactly the one that suits your work can be daunting. When selecting an extruder, there are many things that you should take into account To begin with, consider the type of media you want to use in your project. Various materials may need different kinds of extruders. This another factor related to the previous one: realize now what size do you want for your final item. Your size will dictate the type of extruder you'll need. Finally, decide on what time frame you would like the piece to be completedivityManager! Faster extruders have been designed than others. An important piece of the puzzle to getting them to work well is simply finding an extruder which will fit your specific requirements.

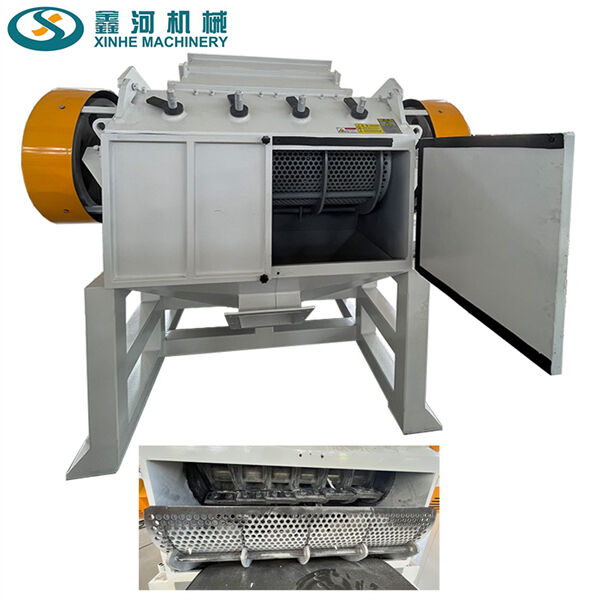

It takes quite a few steps to produce an extruder. The extruder's parts are first modelled in the computer-aided design (CAD) software which is highly specialized to match their designs. FDmXL has been specifically designed to enable designers to build highly detailed models of the extruder parts. The parts are manufactured after the completion of designs through modern technologies such as 3D printing or with CNC (computer numerical control) machines. These techniques are to make the parts accurately as per design and requirements. After each of the components are made, they come together to create an entire extrusion machine. The machine then runs quality tests to ensure it functions properly and passes the company's expectation level before being sold away.

Extruder technology has experienced a range of new benefits making them faster and more efficient than ever. The largest of these being the addition of robots to aid in material handling as well die change for different profiles. Robots can work fast and with more precision, making the production process smoother. The other enhancement is the use of extrusion real-time monitoring gizmo, which houses good computer technology. This way they can guarantee that everything will be done well and the final product might turn out more qualitative. These developments now allow extruders to keep up with the high speeds while they gain repeatability.

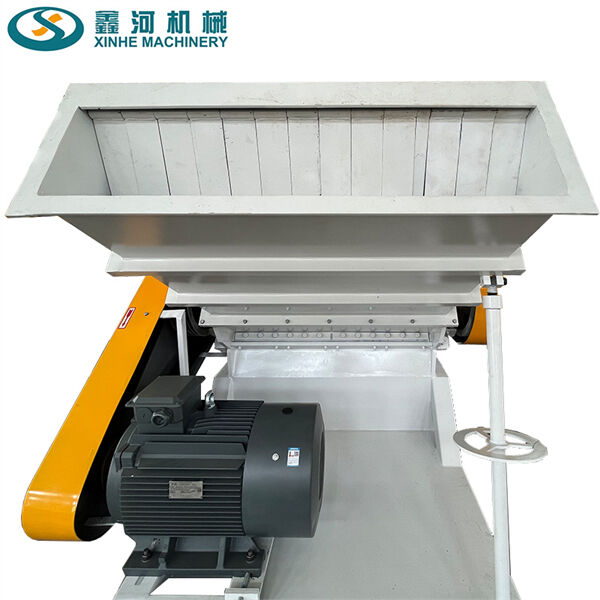

With 12 years of experience in plastic extrusion, we offer machines that can be customized in terms of Extrusion extruder, size, and level of automation. Molds are customizable depending on the final product should look like. We have evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently among China's top 10 extrusion lines for plastic.

We Extrusion extruder the machine configuration to the specific needs of our customers We also provide factory direct sales premium product quality as well as a complete after-sales support Our machines are adored by our customers in Vietnam as well as Indonesia Additionally they enjoy a long lifespan lasting for more than 8 years

At Extrusion extruder we adhere to the strictest standards regarding the material and thickness of machine steel We also provide a detailed list of dangerous parts Ensuring safety measures our manufacturing lines provide high durability with low failure rates and stable reliable production Our customers rely on their machines for an average of more than 8 years

Pre-Sales: Our sales staff, with over Extrusion extruder of experience, will recommend the best machine configuration for you. We provide 7*24h service to our clients and provide videos of the factory.In-Sales: Our videos demonstrate the manufacturing process starting from raw steel through to finished products.After-Sales Services: Our engineers offer services on-site at cost and lifelong technical support via video starting from raw materials until the completed product.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy