In case you are interested in the DIY meaning or considering launch a small production facility, then plastic extrusion is something that I am sure will be of your interest. This process is a unique way of melting, shaping and carving the plastic into finished products that we see in homes every day. If DIY is hard enough for some, you have to even learn the specific technology aka WPC technology. One of the finest inventions for plastic extrusion is WPC (Wood-plastic composite) Here we will see, what an Extruder WPC is and how it could be so lively technology to make the items.

Plastic extrusion is one of the most well-known ways to manufacture various products, and it has served as this purpose for quite some time now From a wide range of products including pipes, tubes and sheets they are used in many forms. But quality has always been an issue for these. In time, they will start to lose colour and bend with ease and eventually break. Regular plastic is bad for our environment too, given it can take many years to decompose and break down sometimes hundreds of years. Here is where WPC technology comes to our aid. When we mix wood fibers, sawdust or even rice husks with this plastic, the result is a type of material much resistant than the original one and has great resistance to long-term erosion passing onto our site.

It is the special WPC technology that makes it possible at all: on an Extruder WPC, which works to first-class results. It really is an invention so brilliant will change the way we perceive plastics and how they are being manufactured. THE SCREW MADE FOR WPC materialsthe story of the screw is unique in being able to work with different types of wpc materials. That way, you can melt them uniformly and get any shape you like! Want to build a shelter, make your own deck or chair, the Extruder WPC can well run all that too!

Its hardness is not very strong, can be used as an extruder WPC. Step 1: Ready Your WPC materials You can mix up different sorts of wood fibers or sawdust with the plastic pellets to form your material blend. Now when you have your mixture ready, you will insert it into the machine through a part known as a hopper. The material will then melt out of the Extruder WPC, where it is melted down in short time. Failed that, the melton WPC will be following a special region namely die and you will get your required designed product. The resulting product will be ready to cool down completely and cut accordingly. Voila, you have made a resilient and sustainable product that is also environmentally conscious enough to last for years!

Extruder WPC is that it has the ability to create quite a diverse range of other products. Create fence posts, rails and garden or yard pickets It will also be used to produce decking, flooring and wall panels for the residential or office interiors. You can also produce outdoor furniture, equipment to be used in playgrounds and even car components from these. Extruder WPC prompts the creative room: possibilities for what one can produce with Extruder WPC are literally unlimited.

An additional amazing thing about Extruder WPC is that we can make use of the waste.: instead transforming garbage into composite products properties. They are made from waste materials such as wood fibers, sawdust and rice husks that would otherwise be burned to clear landfills. We can make that waste wood with Extruder WPC to a very strong and durable long life product. This method is important because it not just aids in keeping the waste away from landfills but also lowers down the necessity of producing fresh plastic content. It is not incorrect to say that hence, Extruder WPC is too-friendly-to-environment technology which takes us close to our planet.

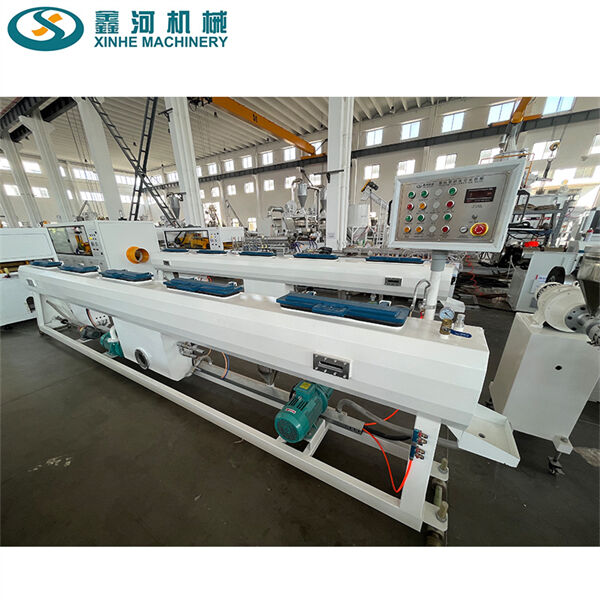

We adhere to the strictest standards for Jiangsu Xinhe for machine steel thickness and materials We also offer an inventory of components that are vulnerable The Extruder wpc we use are built to guarantee safety and have a long life expectancy as well as a low rate of failure and stable efficient production Many of our customers have utilized their machines for more than eight years

Our machines are arranged to meet the needs of the customer We provide direct sales from the factory premium products and an extensive after-sales support Our machines are highly valued by our customers in Vietnam as well as Extruder wpc They also have an extended life span which is more than eight years

With 12 years of experience in plastic extrusion, we offer machines that can be customized in terms of Extruder wpc, size, and level of automation. Molds are customizable depending on the final product should look like. We have evolved from Zhangjiagang Xinhe Machinery into Jiangsu Xinhe Intelligent Equipment Co. Ltd. and we are currently among China's top 10 extrusion lines for plastic.

Pre-Sales: Our sales staff with more than five years of experience, will Extruder wpc the best machine configuration for you. We provide 24 hour service to our clients and offer video tours of the factory.In-Sales: We can provide videos of production, from raw steel to the finished product as well as videos of production on the total line.After-Sales Service: Our engineers offer on-site support for cost and lifelong technical support via video from raw materials to the finished product.

Copyright © Jiangsu Xinhe Intelligent Equipment Co., Ltd. All Rights ReservedPrivacy Policy